A brand new examine from the Tokyo College of Science reveals a machine-learning-assisted technique that dramatically improves the accuracy of carbon nanotube (CNT) yarn 3D printing, decreasing geometric errors by almost 80%. Revealed in Composites Half C: Open Entry, the analysis by Junro Sano and Ryosuke Matsuzaki demonstrates how an explainable AI mannequin can robotically right printing deviations by pinpointing filament twist, not diameter, as probably the most essential issue for precision.

Machine studying for fiber-based precision

Typical steady carbon-fiber-reinforced polymer (CCFRP) 3D printing depends on thick, brittle filaments that restrict the achievable curvature of printed elements usually bigger than 1.5 mm. CNT yarns, against this, have nanoscale diameters and better flexibility, making them splendid for superb, curved geometries.

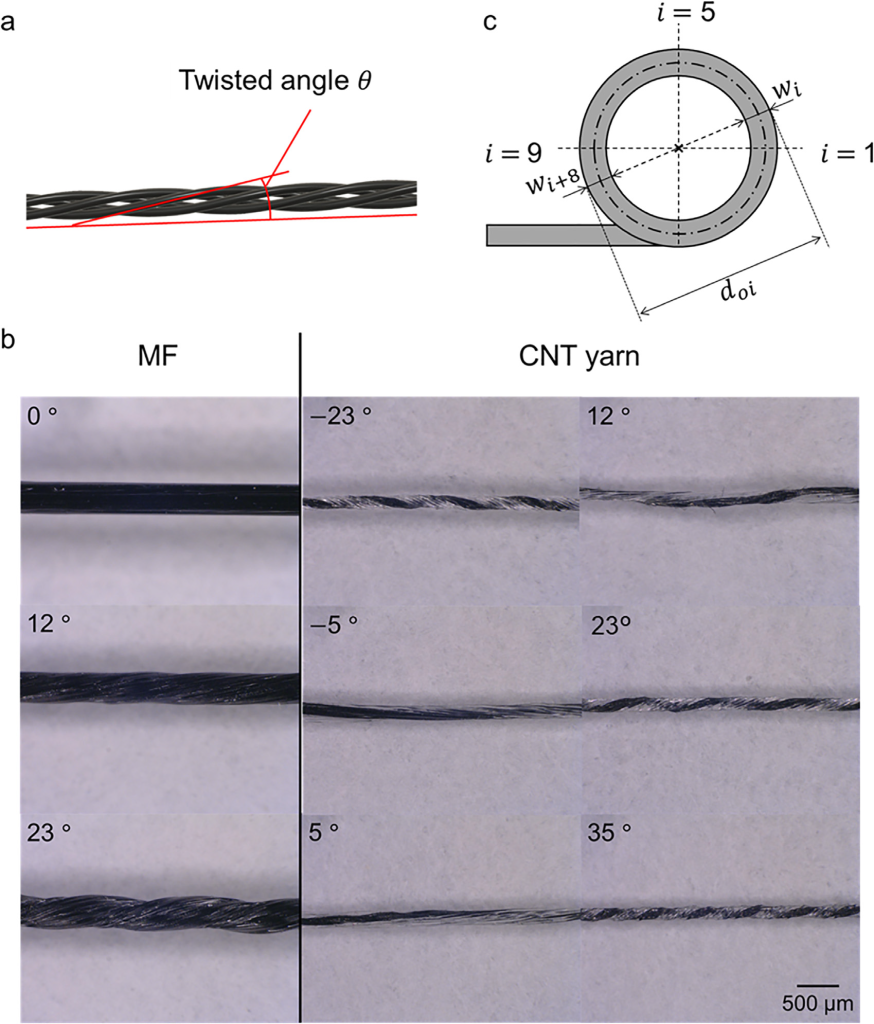

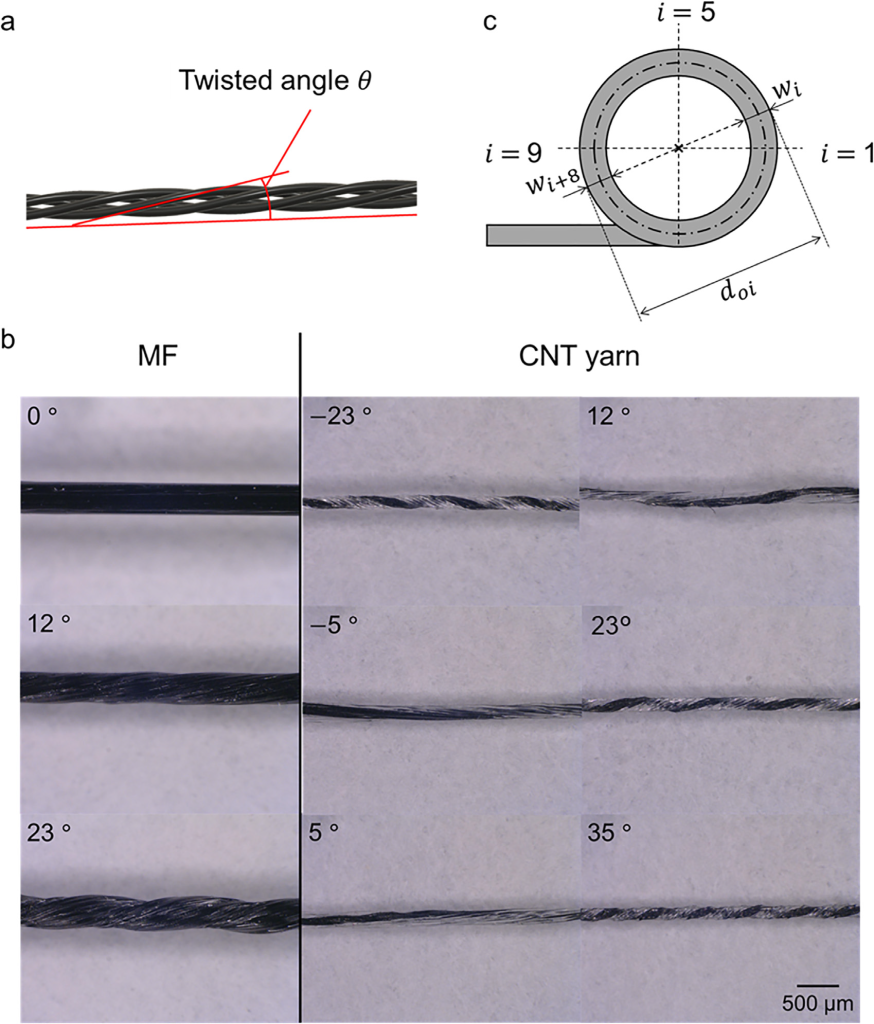

To quantify how yarn twist and diameter affect print high quality, the researchers 3D printed round check paths utilizing CNT yarns (0.15 mm) and Markforged-type carbon fiber filaments (0.4 mm) below various twist angles, starting from -23° to 35°. They measured radius deviation and width variation below a microscope and used a LightGBM machine studying mannequin, interpreted with SHAP evaluation, to find out which parameters most affected accuracy.

Twist outperforms diameter for precision

The SHAP evaluation revealed a beforehand unknown relationship: the interplay between printing route and twist angle dictates whether or not deposited fibers deviate inward or outward. This perception proved essential. The staff discovered that filament twist, not its small diameter, was the dominant consider minimizing radius errors in curved paths.

By making a suggestions loop that fed the mannequin’s predictions again into the printer’s settings, they achieved a 79.3% discount in radius error, enabling the printing of circles with radii as small as 0.7 mm. The mannequin’s predictive accuracy was validated with an R² worth of 0.891.

From lab to light-weight drones

To reveal real-world feasibility, the staff 3D printed a drone-arm part utilizing their feedback-controlled course of. The half printed with out suggestions confirmed noticeable shrinkage in comparison with the design, whereas the feedback-corrected half carefully matched meant dimensions, showcasing the potential of ML-optimized CNT yarn printing for light-weight composite purposes.

Towards data-driven composite manufacturing

The examine highlights how explainable machine studying will help enhance precision in continuous-fiber additive manufacturing by robotically compensating for geometric deviations. In response to the authors, the strategy may very well be prolonged to fiber-reinforced thermoplastics and different complicated curvature geometries, paving the best way for smarter, data-driven composite fabrication.

The examine provides to a rising physique of analysis exploring how synthetic intelligence and data-driven management can enhance additive manufacturing precision. Earlier this 12 months, Aalen College researchers launched a high-precision monitoring system to spice up print reliability and allow adaptive corrections throughout steel printing. In parallel, machine studying has been used to speed up direct vitality deposition analysis, serving to predict course of outcomes and optimize parameters in actual time. A separate examine on AI-controlled 3D printing additionally demonstrated measurable beneficial properties in dimensional accuracy and consistency.

Collectively, these developments level towards a way forward for closed-loop, self-correcting additive manufacturing, the place fashions just like the one developed by Sano and Matsuzaki convey fiber-reinforced composites into the identical clever manufacturing paradigm.

Whilst you’re right here, why not subscribe to our YouTube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Need to assist form the way forward for AM? Be a part of the 3DPI Knowledgeable Committee.Characteristic picture exhibits illustration of probably the most generally utilized 3D printing methods. Picture by way of Hossain et al., ChemPhysMater (2025).

Featured picture exhibits the connection between printing route and twisted angle. Picture by way of Sano & Matsuzaki / Tokyo College of Science.