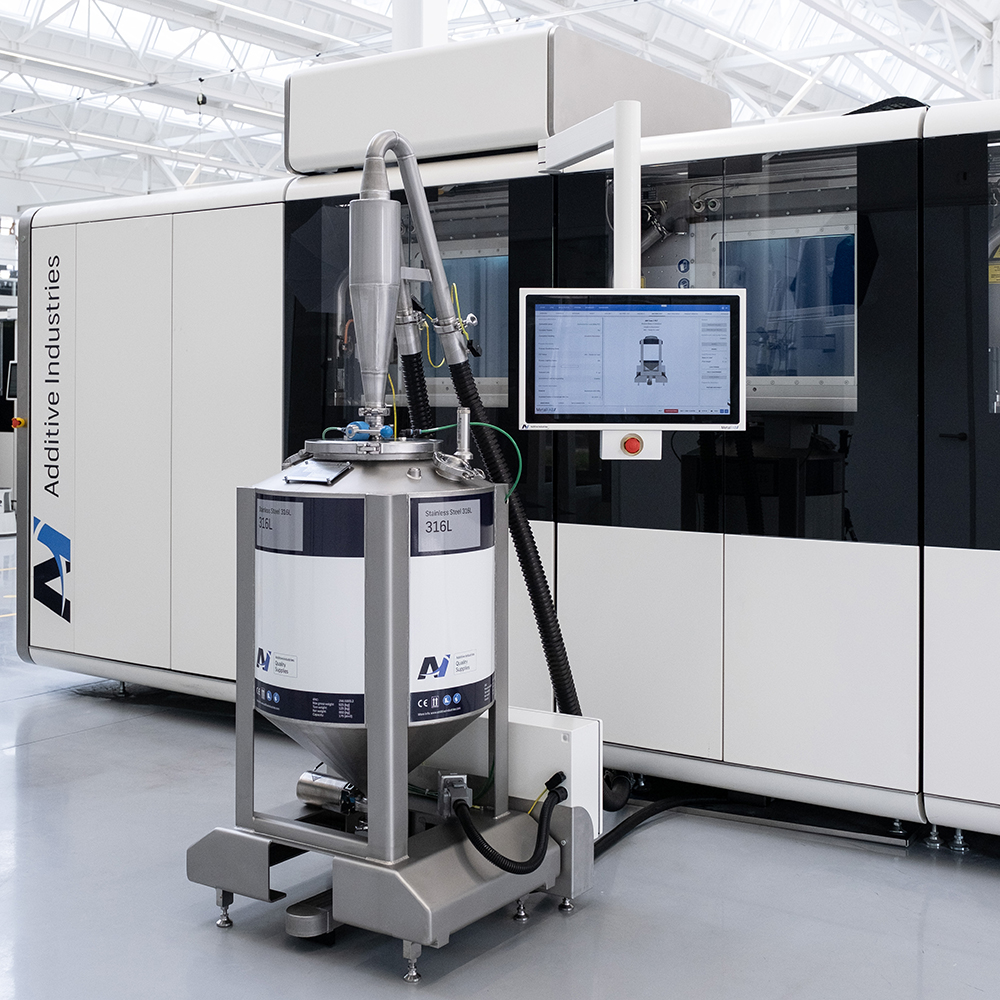

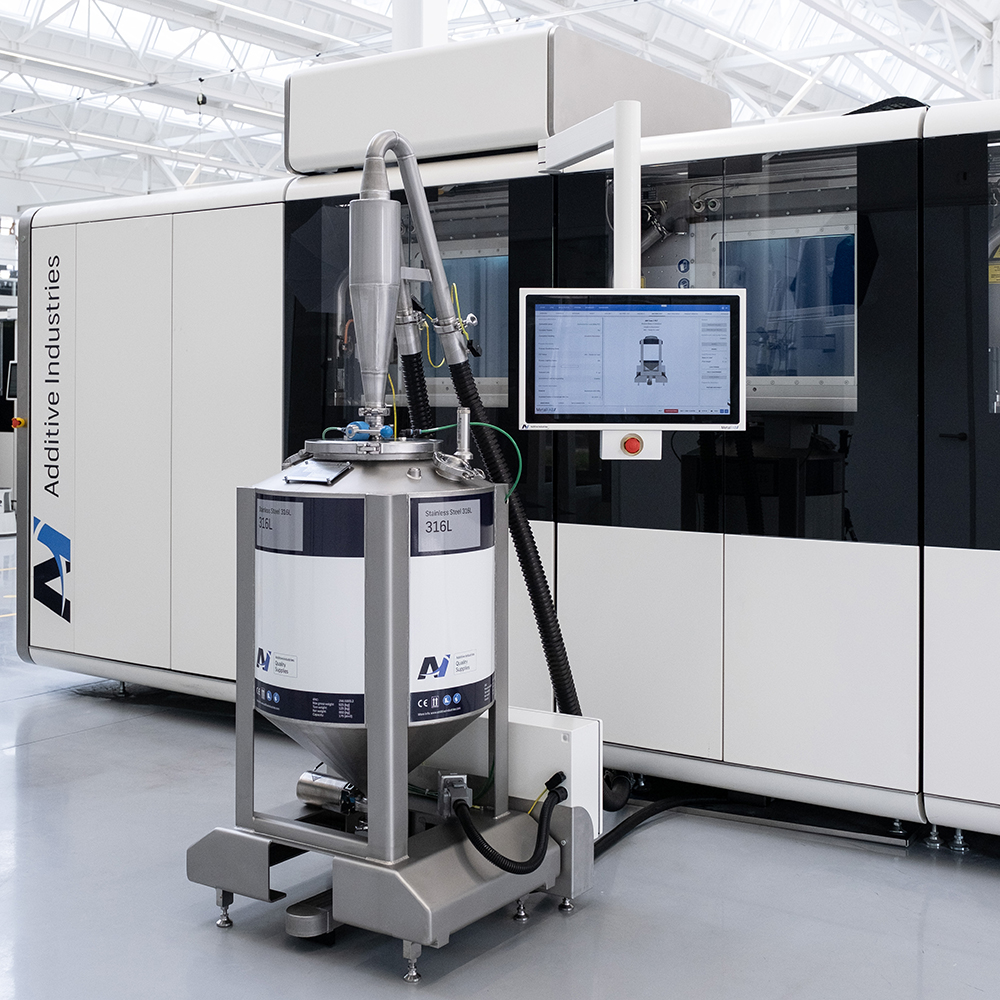

Sandvik, a provider of gas-atomized metallic powders, and Additive Industries, developer of the MetalFab platform for laser powder mattress fusion, have partnered to streamline powder dealing with workflows in metallic 3D printing. The collaboration introduces a direct powder filling and transport answer utilizing the Powder Load Device (PLT), a 175-liter sealed hopper designed for integration with MetalFab methods. Prospects can now order Sandvik powder pre-filled in PLTs and shipped instantly from Sweden below inert situations, enabling direct loading into printers with out operator publicity.

Additive Industries’ MetalFab helps automated loading and unloading, and the PLT connects on to this setup. Sandvik will initially provide three powders via this system: Osprey 718 (a nickel-based superalloy), Osprey 316L chrome steel, and Osprey Ti-6Al-4V-ELI (Grade 23) titanium alloy. Every PLT unit can carry as much as 600 kilograms of metal powder, relying on materials density. The containers are examined and licensed for transport by highway, rail, and sea. By eliminating guide powder transfers and sustaining inert situations from atomization via printing, the system is designed to scale back contamination danger, enhance traceability, and decrease dealing with hazards.

Powder id verification is supported by sensors inside each the PLT and MetalFab system, guaranteeing appropriate materials loading. Storage and transport stay inert from supply to level of use. In line with Additive Industries, the PLT reduces reliance on single-use plastics whereas additionally reducing the necessity for native powder storage at manufacturing websites. By conserving unused powder constantly sealed when not in use, operators can entry materials on demand—even throughout an energetic construct—with out reconditioning.

“Because the main developer and producer of gas-atomized metallic powder for a variety of superior manufacturing applied sciences, we’re joyful to associate with Additive Industries to supply the market a state-of-the-art metallic powder provide answer,” mentioned Andrew Coleman, VP Enterprise Unit AM, Powder Options at Sandvik. “We’re dedicated to utilizing engineering and innovation to make the shift in direction of extra industrial options and the PLT is a pure addition to enabling elevated effectivity and security for our clients’ workers. We stay up for persevering with pushing the boundaries of metallic powder for additive manufacturing applied sciences.”

Mark Massey, CEO of Additive Industries, added: “We recognise the vital nature of the powder feedstock in our methods, each from a top quality and security perspective, which is why the MetalFab is designed to minimise publicity of powder particles to oxygen, moisture and human contact. The PLT permits materials to be packaged and maintained in inert situations instantly on the manufacturing supply and transported direct to web site in bulk portions, avoiding the necessity for plastic containers, the place it may be loaded instantly into the MetalFab system. Additional, it ensures that powder not within the MetalFab is continually saved below inert situations when related, and could be loaded to the system at any level it’s wanted, together with whereas the system is printing.”

Additive Industries is headquartered in Eindhoven, the Netherlands, and supplies modular metallic 3D printing methods designed for high-throughput environments in aerospace, automotive, high-tech, and vitality sectors. Sandvik is a world engineering group centered on manufacturing, mining, and infrastructure purposes, with operations in over 150 nations. In 2024, the corporate reported revenues of SEK 123 billion and employed roughly 41,000 folks.

AMAA 2025 is right here. One occasion. Numerous insights. Safe your house now.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to remain up to date with the newest information and insights.

Featured picture exhibits an operator inspects superior powder dealing with gear at Sandvik’s manufacturing web site. Photograph by way of Additive Industries.