On this article, we assessment the Bambu Lab H2D Professional, the corporate’s newest skilled entry into high-temperature, multi-material FFF 3D printing.

On the coronary heart of this new machine is the Bambu Imaginative and prescient Encoder, an optical suggestions system that delivers closed-loop movement correction for improved dimensional accuracy at pace, a function not often seen in desktop FFF programs. Via a program of calibration routines, dimensional benchmarks, and utility exams, our engineering workforce assessed how this expertise and the broader system round it compares with rivals within the skilled desktop market.

Shenzhen-based Bambu Lab has constructed its popularity on high-performance, automated desktop 3D printers tightly built-in with its personal software program ecosystem. With the H2D Professional, the corporate is concentrating on skilled customers who require dependable multi-material workflows and engineering-grade outcomes.

Positioned as a dual-nozzle, production-ready platform, the H2D Professional combines tungsten-carbide nozzles, a compact dual-extrusion toolhead, and a 350 × 320 × 325 mm construct quantity inside an actively heated enclosure. These options are aimed toward constant throughput with abrasive and technical filaments. The machine sits inside Bambu’s linked ecosystem (MakerWorld, Bambu Studio, Bambu Useful) and provides enterprise-friendly networking, together with WPA2-Enterprise Wi-Fi and Ethernet.

In contrast with earlier Bambu machines, the Professional introduces mechanical refinements resembling a foldable filament cutter, built-in nozzle wiper, bolstered AMS feed path, and computerized nozzle-offset calibration to enhance reliability in multi-material jobs.

On this article, we put these claims to the check by in depth benchmarks and real-world utility exams.

What makes the H2D Professional stand out?

The H2D Professional builds on Bambu Lab’s popularity for automation and high-speed printing, however introduces a number of professional-grade refinements aimed toward consistency and materials versatility. Its dual-nozzle extruder is fitted with tungsten-carbide suggestions, providing prolonged sturdiness and dependable efficiency with abrasive filaments resembling PA-CF, ASA-CF, and different composite supplies. The actively heated chamber, reaching as much as 65 °C, permits for secure processing of technical polymers, together with PA6-CF, PC, and ASA.

Bambu H2D Professional toolhead and nozzles. Picture by 3D Printing Business.

One other standout element is the Bambu Imaginative and prescient Encoder, an optical suggestions system that elevates the printer past the open-loop movement management frequent in most FFF machines. As a substitute of relying solely on stepper motor alerts, the Imaginative and prescient Encoder visually tracks the toolhead’s precise place in opposition to its commanded path, enabling a type of closed-loop management.

This strategy addresses a number of frequent challenges in high-speed extrusion. By straight monitoring motion, the encoder can detect skipped steps, backlash, or resonance-induced drift and apply real-time corrections. This ensures that even when the printer accelerates to twenty,000 mm/s² or reaches toolhead speeds of 600 mm/s, dimensional accuracy and repeatability are maintained. In sensible phrases, this reduces ovality in round elements, minimizes cumulative drift in lengthy builds, and helps protect tight tolerances throughout giant print jobs.

Bambu Lab H2D Professional imaginative and prescient encoder. Picture by 3D Printing Business.

The Imaginative and prescient Encoder additionally underpins most of the H2D Professional’s automated calibration routines. It assists with gantry alignment, XY offset tuning in dual-extrusion mode, and movement accuracy checks throughout the complete construct plate. When utilized in mixture with the printer’s toolhead digital camera and slicer-based compensation options, the encoder simplifies setup, improves first-layer consistency, and contributes to long-term mechanical stability with out the necessity for handbook changes.

Its worth was most clearly demonstrated throughout benchmark testing. Preliminary round trajectory exams confirmed deviations exterior skilled tolerances, however when paired with PLA-CF filament and Bambu Studio’s Auto Circle Contour-Gap Compensation, accuracy improved dramatically to 0.044 mm imply deviation with a 0.021 mm customary deviation. These outcomes spotlight the encoder’s function in reworking uncooked {hardware} pace into engineering-grade precision, particularly in geometry-sensitive purposes resembling press-fits or sealing surfaces.

The printer ships with each the AMS 2 Professional and AMS HT items as customary. These modules present moisture-controlled storage, RFID-tag recognition, and automatic filament switching. When chained, the system helps as much as 24 spools, giving customers vital flexibility in multi-material manufacturing, whereas minimizing handbook intervention throughout lengthy jobs.

Bambu Lab AMS system. Picture by 3D Printing Business.

Further refinements distinguish the Professional from earlier Bambu machines. These embody a foldable filament cutter for cleaner instrument modifications, an built-in nozzle wiper to stop first-layer contamination, and a bolstered AMS feed path that reduces jamming threat when utilizing powerful, fiber-reinforced filaments. Collectively, these updates enhance uptime, materials compatibility, and ease of upkeep.

Design and Construct: Contained in the H2D Professional

The H2D Professional arrives in a thoughtfully engineered package deal, with twin AMS items and equipment saved securely contained in the construct chamber. Dense foam inserts and air cushions stop any shifting throughout transit, whereas hand slots and taped panels make lifting and setup simple. The complete unboxing course of was simple and solely took roughly quarter-hour utilizing solely a hex key.

Structurally, the 3D printer is constructed on a inflexible metal and aluminum chassis with a CoreXY movement system able to accelerations as much as 20,000 mm/s². This ensures stability and pace, whereas the three-point Z-axis kinematics present constant mattress motion throughout the complete 325 mm construct peak. A glass entrance door and actively heated chamber (as much as 65 °C) allow the profitable printing of technical filaments like PA6-CF and PC, lowering warping and layer separation

On the coronary heart of the system is the dual-nozzle extruder, designed for speedy materials modifications and outfitted with tungsten-carbide nozzles for abrasion resistance. The heated mattress reaches 120°C and helps clean and textured PEI plates, backed by computerized mesh leveling for dependable first layers.

On the usability aspect, the Professional incorporates a 5-inch capacitive touchscreen, USB and Ethernet connectivity, and WPA2-Enterprise Wi-Fi, making it deployment-ready for skilled environments. A side-mounted spool holder gives direct extrusion paths for versatile filaments resembling TPU, complementing the twin AMS modules included as customary.

Collectively, these {hardware} selections steadiness pace, sturdiness, and accessibility, reinforcing the Professional’s positioning as a professional-grade FFF platform.

Software program and Workflow: Bambu Studio on the Core

The H2D Professional operates inside Bambu Lab’s closed software program ecosystem, anchored by Bambu Studio, the corporate’s in-house slicing and gadget administration platform. For this assessment, our workforce used a growth version, which included full assist for the H2D Professional.

Bambu Studio gives a streamlined workflow from mannequin import to print execution. Its Put together workspace permits customers to assign supplies per nozzle, configure helps, and apply modifiers, whereas slicing is optimized for the printer’s CoreXY structure. Efficiency was responsive all through, with slicing speeds outpacing most third-party software program.

A significant benefit of the ecosystem is MakerWorld, Bambu Lab’s built-in library of shared and pre-configured print recordsdata. Fashions may be downloaded straight into Bambu Studio with pre-set orientation, helps, and materials assignments, lowering preparation time. Designers can even add their very own initiatives, share technical notes, and obtain suggestions by a built-in reward system.

The H2D Professional’s dual-extruder configuration is nicely supported, with intuitive controls for materials switching, purge quantity, and prime tower setup. Superior options, resembling adaptive layer peak, gap/shaft compensation, ironing, and fuzzy pores and skin, are inbuilt for fine-tuning skilled workflows. Materials presets are mechanically utilized when RFID-tagged Bambu filaments are loaded by the AMS, minimizing consumer error and making certain right temperature and stream parameters.

Monitoring and distant administration are built-in by the System tab in Bambu Studio and the Bambu Useful cellular app. Customers can entry real-time print statistics, view a stay digital camera feed, alter parameters, and even cancel jobs remotely. Cloud connectivity extends this additional, although safe deployment is feasible through native LAN or WPA2-Enterprise Wi-Fi.

Total, the software program reinforces Bambu Lab’s “plug-and-print” philosophy. Whereas the closed format limits G-code export for non-Bambu machines, the tight integration ensures reliability and pace for H2D Professional customers.

Placing the H2D Professional to the Take a look at

Our benchmarking exams mixed dimensional accuracy checks, repeatability measurements, and our inside 3DPI check mannequin, designed to guage consistency throughout frequent failure modes resembling overhangs, bridges, and retraction.

Repeatability exams measure how constantly a printer can reproduce the identical geometry over a number of runs. We evaluated a set of normal shapes, squares, hexagons, and tubes, with a goal customary deviation of ≤0.1 mm throughout dimensions. The H2D Professional carried out nicely inside this vary, attaining deviations constantly beneath 0.05 mm. Z-axis efficiency was significantly robust, displaying near-perfect layer peak management.

Accuracy, assessed by evaluating printed dimensions to CAD values, was extra geometry-dependent. For round options resembling holes and contours, our goal threshold was ≤0.1 mm. In default PLA profiles, the H2D Professional tended to undershoot, with deviations of 0.1–0.15 mm. Whereas this falls exterior our benchmark tolerance, it may very well be corrected utilizing Bambu Studio’s built-in compensation instruments.

The round trajectory check evaluates how precisely a printer can reproduce spherical geometries, which is important for elements requiring press-fits, bearing seats, or sealing surfaces. We measure ovality by evaluating the printed half’s X and Y dimensions in opposition to a nominal circle. For skilled FFF programs, a imply deviation of ≤0.1 mm is our goal threshold for acceptable accuracy.

In preliminary exams utilizing default PLA profiles, the H2D Professional produced measurable ovality, with a imply deviation of 0.147 mm, exterior the benchmark tolerance. After retesting with Bambu’s PLA-CF and enabling the experimental Auto Circle Contour-Gap Compensation function in Bambu Studio, accuracy improved considerably to a imply deviation of 0.044 mm with a normal deviation of 0.021 mm. These outcomes not solely met however comfortably surpassed our goal, confirming the significance of slicer compensation in realizing the complete advantage of the printer’s Imaginative and prescient Encoder–assisted movement management.

Measured course of functionality cylinders on Fusion. Photos by 3D Printing Business.

Course of functionality testing evaluates whether or not a printer can constantly produce elements inside specified tolerances. Utilizing statistical indices (Cp, Cpk, and Cpm), we assess each the unfold and centering of dimensional outcomes in opposition to nominal CAD values. For skilled FFF programs, a Cp or Cpk above 1.33 is often thought of acceptable, whereas values above 2.0 point out glorious repeatability.

150 cylinder elements within the slicer and 150 3D printed cylinder elements. Picture and photograph by 3D Printing Business.

In our exams, the H2D Professional considerably exceeded these thresholds, attaining a Cp of 6.49 and a Cpk of three.65, each nicely past the minimal customary for succesful processes. These figures spotlight the system’s means to ship tight, repeatable outcomes throughout repeated prints. Nonetheless, the Cpm worth of 0.75 revealed a constant systematic offset, which means that whereas elements have been dimensionally constant, they weren’t all the time completely centered on the nominal CAD values. This misalignment may be addressed by making use of slicer-based dimensional compensation.

The Professional efficiently printed unsupported overhangs as much as 65°, with solely minor bulging at 50°. Retraction efficiency was glorious, displaying no seen stringing in spike exams. Bridging prolonged cleanly to 60 mm spans, far past the everyday 15 mm baseline for many FFF printers. A full-height 325 mm tower printed with out defects or wobble, confirming Z-axis stability, whereas the perimeter check validated the complete 350 × 320 mm construct space with seamless nozzle transitions throughout the plate.

Tower, overhang, and retraction check elements. Images by 3D Printing Business.

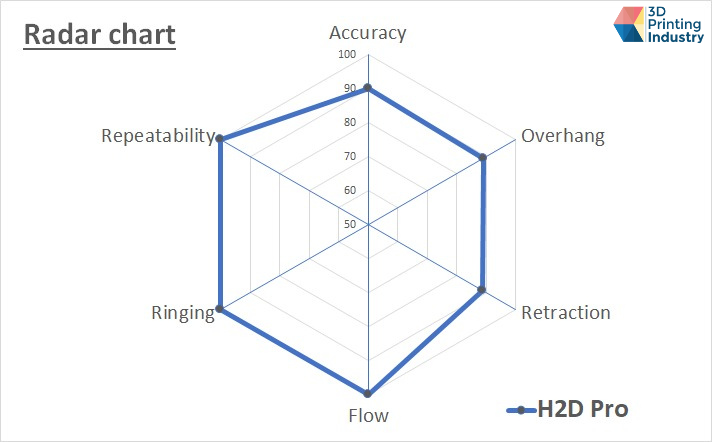

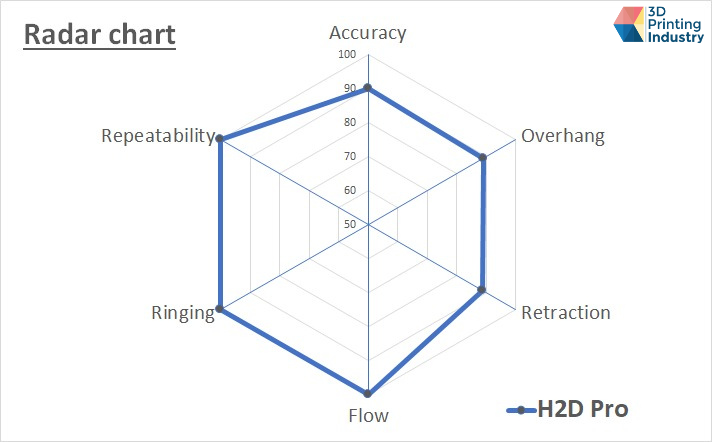

3DPI benchmark rating

To consolidate efficiency throughout classes, we apply the 3DPI benchmarking suite, a standardized set of check fashions that evaluates key features of FFF printing: repeatability, stream management, overhangs, bridging, retraction, floor high quality, dimensional accuracy, and ghosting suppression. Every metric is scored individually after which mixed right into a weighted whole out of 100. For desktop FFF printers, a rating above 60/100 signifies robust general efficiency, whereas scores above 70/100 place a system within the prime tier of the market.

The H2D Professional achieved a complete rating of 89.8/100, positioning it on the prime finish of desktop-class FFF machines. It excelled in repeatability, bridging, and ghosting suppression, reflecting each the rigidity of its CoreXY movement system and the corrective capabilities of the Imaginative and prescient Encoder. Retraction efficiency was additionally robust, with minimal stringing seen on stress exams.

Benchmark check 3D printed at customary print pace. Picture by 3D Printing Business.

Total, the Professional’s rating displays a system with distinctive mechanical stability, accuracy, and reliability, able to dealing with a variety of supplies and geometries with minimal intervention. Its near-perfect consequence firmly establishes it among the many most succesful desktop FFF platforms we’ve got examined thus far.

Actual-World Functions: From Prototypes to Useful Components

Subsequent, we evaluated the H2D Professional with a spread of practical utility prints spanning automotive, tooling, and versatile supplies. The objective was to validate whether or not the machine’s specs translate into usable elements for real-world engineering workflows. We began with a bike brake air scoop, which we printed in PLA-CF. The half demonstrated a clear floor end, secure geometry, and correct helps.

Air Scoop print consequence. Images by 3D Printing Business.

Following this, our workforce 3D printed a PET-CF winglet utilizing HIPS as a assist materials. This highlighted the flexibility of the H2D Professional’s chamber to stop warping when processing composite supplies. The ensuing half was strong sufficient for aerodynamic analysis, confirming the brand new 3D printer’s value for producing practical prototypes.

Winglet print consequence. Images by 3D Printing Business.

A bigger ASA dirtbike headlight fairing was additionally printed. This achieved a exact match and clear HIPS assist elimination, confirming dimensional accuracy on cumbersome geometries.

Headlight fairing print consequence. Images by 3D Printing Business.

Instruments and workshop elements

Leveraging its dual-nozzle setup, our H2D Professional subsequent 3D printed a bike clutch basket instrument in PC and ASA-CF, combining clear outer partitions with fiber-reinforced inserts.

The consequence was a cheap instrument with seen inside reinforcement, appropriate for actual workshop use. Equally, a generative-design automotive bracket in PETG and HIPS printed cleanly, validating the machine’s potential in prototyping complicated geometries.

Clutch instrument print. Images by 3D Printing Business.

Versatile and high-temperature supplies

The Professional’s side-mounted direct-feed spool holder enabled clean dealing with of TPU, which might usually show problematic on Bowden-style programs. We printed a dual-TPU funnel combining 95A and 70A shore hardness filaments, confirming the toolhead’s means to transition between versatile grades with out jams or feeder slip. Layer adhesion was robust, and the funnel retained its supposed elasticity, although residual moisture within the filament produced some floor effervescent, highlighting the significance of pre-drying elastomers even when utilizing the AMS.

Funnel print consequence. Images by 3D Printing Business.

On the different finish of the spectrum, the actively heated chamber proved important in processing PA6-CF, a notoriously warp-prone nylon composite. We printed a full-height inlet manifold at 325 mm Z, with chamber temperature stabilized at 65 °C. The half maintained constant adhesion throughout the bottom layers and confirmed no seen warping or delamination, a consequence troublesome to realize on unenclosed desktop printers. Floor end was matte and uniform, and the half’s stiffness steered it may very well be deployed in engine-bay situations with out deformation.

Inlet manifold print. Picture by 3D Printing Business.

A Skilled-Grade Platform with out the worth tag

Bambu Lab’s H2D Professional delivers professional-grade 3D printing at a consumer-friendly worth of simply $3,799.

In benchmarking, the 3D printer delivered glorious repeatability and robust Z-axis management. Its general benchmark rating of 89.8/100 locations it among the many strongest desktop FFF programs we’ve got examined, with specific strengths in bridging, ghosting suppression, and repeatability.

Stress exams confirmed overhangs as much as 65°, bridges spanning 60 mm, and course of functionality indices far above the 1.33 trade threshold, underscoring its consistency in high-speed operation.

In utility testing, the H2D Professional constantly delivered dependable, application-ready elements throughout various engineering situations. A bike brake air scoop printed in PLA-CF confirmed clear surfaces and secure geometry, whereas a PET-CF winglet highlighted the chamber’s means to suppress warping in composites. Bigger elements, resembling an ASA dirtbike headlight fairing, maintained dimensional accuracy with HIPS helps detaching cleanly after printing.

Workshop tooling additionally proved viable, with a PC/ASA-CF clutch basket instrument demonstrating inside reinforcement and a PETG/HIPS automotive bracket validating its means to deal with complicated geometries. On the materials extremes, the direct-feed spool holder enabled clean TPU printing with out jams, whereas the heated chamber stabilized a full-height PA6-CF inlet manifold, producing an element appropriate to be used in engine-bay situations.

Caveats embody prolonged calibration routines, occasional oversensitivity in AI failure detection, and a footprint which may be giant for smaller workspaces. Nonetheless, these drawbacks are outweighed by constant accuracy and a beneficiant construct envelope, strong integration with Bambu Studio, and enterprise-grade networking choices. For engineers, SMEs, and analysis teams looking for a dependable, production-ready FFF resolution, the H2D Professional stands out as probably the most succesful programs at present available on the market.

The Bambu Lab H2D Professional demonstrates a excessive stage of engineering maturity, combining pace, automation, and materials versatility in a system aimed squarely at skilled customers. Its dual-nozzle hotend, actively heated chamber, and AMS ecosystem make it well-suited to multi-material workflows and demanding engineering polymers.

Throughout our exams, the H2D Professional constantly translated its specs into practical elements with minimal post-processing. By pairing high-speed movement with the precision of its Imaginative and prescient Encoder, Bambu Lab has created a desktop FFF platform that bridges the hole between speedy prototyping and reliable small-batch manufacturing.

Technical specs of the Bambu Lab H2D Professional

| Class | Specification | |||||

| Construct Quantity | Single-nozzle: 325 × 320 × 325 mm |

Twin-nozzle: 300 × 320 × 325 mm |

Whole supported: 350 × 320 × 325 mm |

|||

| Machine Dimensions | 492 × 514 × 626 mm | |||||

| Weight | 31 kg | |||||

| Nozzle Sort | Tungsten carbide nozzle | |||||

| Max Nozzle Temp | 350 °C | |||||

| Filament Diameter | 1.75 mm | |||||

| Max Stream Price | Commonplace hotend: 40 mm³/s | Excessive-flow hotend: 65 mm³/s | ||||

| Max Velocity of Toolhead | 1000 mm/s | |||||

| Max Acceleration | 20,000 mm/s² | |||||

| Precision | Optical movement calibration (~5 µm precision) | |||||

| Heated Mattress | As much as 120 °C | |||||

| Heated Chamber | As much as 65 °C | |||||

| Construct Floor | Clean PEI or textured PEI sheet | |||||

| Cooling System | Closed-loop followers for half cooling, hotend, chamber, and exhaust | |||||

| Air Filtration | Pre-filter (G3), HEPA H12, activated carbon (coconut shell) | |||||

| Cameras | Hen’s Eye (3264 × 2448), nozzle view, toolhead, 1080p live-view | |||||

| Sensors | Filament run-out, tangle detection, odometry, power-loss restoration, chamber door | |||||

| Touchscreen | 5″ capacitive, 720 × 1280 decision | |||||

| Storage & Interface | 32 GB eMMC, USB, cloud, Bambu Studio, cellular app | |||||

| Processing Unit | 2 TOPS Neural Processing Unit (NPU) | |||||

| Energy Provide | 100–120 VAC or 200–240 VAC, 50/60 Hz | |||||

| Max Energy Draw | 1320 W (110 V), 2200 W (220 V) | |||||

| Supported Supplies | PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, glass/carbon fiber composites, together with PPA-CF/GF, PPS-CF/GF |

|||||

Need to be taught extra about vitality innovation in 3D printing? Be part of our upcoming digital occasion on 3D printing in nuclear, renewables, oil & gasoline, turbomachinery, and past.

Need to assist form the way forward for AM? Be part of the Professional Committee for our 2025 3DPI Awards, launching later this summer season.

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our YouTube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits the Bambu Lab H2D Professional. Picture by 3D Printing Business.