Think about being on the moon; surrounded by lots of of thousand ft2 of area. A lot of the exercise you see is robotic – automated material-handling techniques transferring issues from level A to B. The few individuals round are sporting “bunny fits” [1] and masks. They appear like astronauts – they don’t seem to be. You aren’t in area, you might be within the clear room of considered one of Intel’s chip manufacturing services.

These services are subtle, managed environments the place disruptions are extraordinarily pricey. In right here, we produce cutting-edge microchips, the place a single chip may be made from 28 billion transistors. One hour of downtime can price us as much as $5M in income loss, which is why plenty of these factories run for years with none downtime. However, our cutting-edge services require fashionable, state-of-the-art infrastructure, which creates a conundrum:

How do you modernize your infrastructure with zero-downtime?

This yr, my crew received the CX Buyer Hero of the 12 months Award for our infrastructure modernization challenge. On this weblog, I clarify why.

Intel’s Foundry Shift: Architecting for a New Period

In 2021, Intel introduced its intention to change into a “foundry” for the semi-conductor market, opening our services to exterior prospects to fabricate their merchandise.

This transfer meant that we would have liked to scale up and modernize our manufacturing capability. It additionally required advancing our safety posture to guard our and our prospects’ mental property from unhealthy actors’ more and more elaborate safety threats.

Traditionally, we relied on Digital Entry Management Lists (VACLs) to handle the visitors movement between 1000’s of instruments. These VACLs had grown into extremely lengthy and complicated lists, tough to handle, and incapable of scaling to the intricate calls for of our new foundry enterprise. We wanted an entire re-architecture.

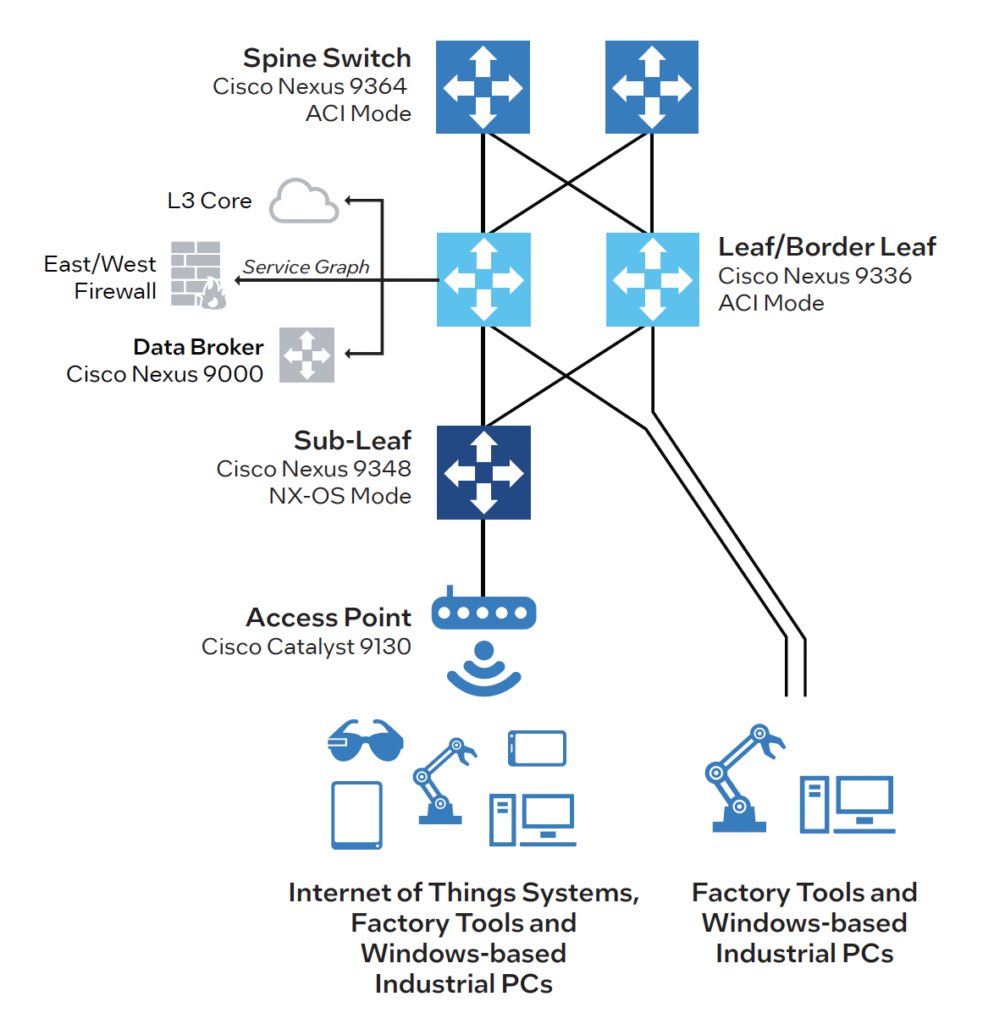

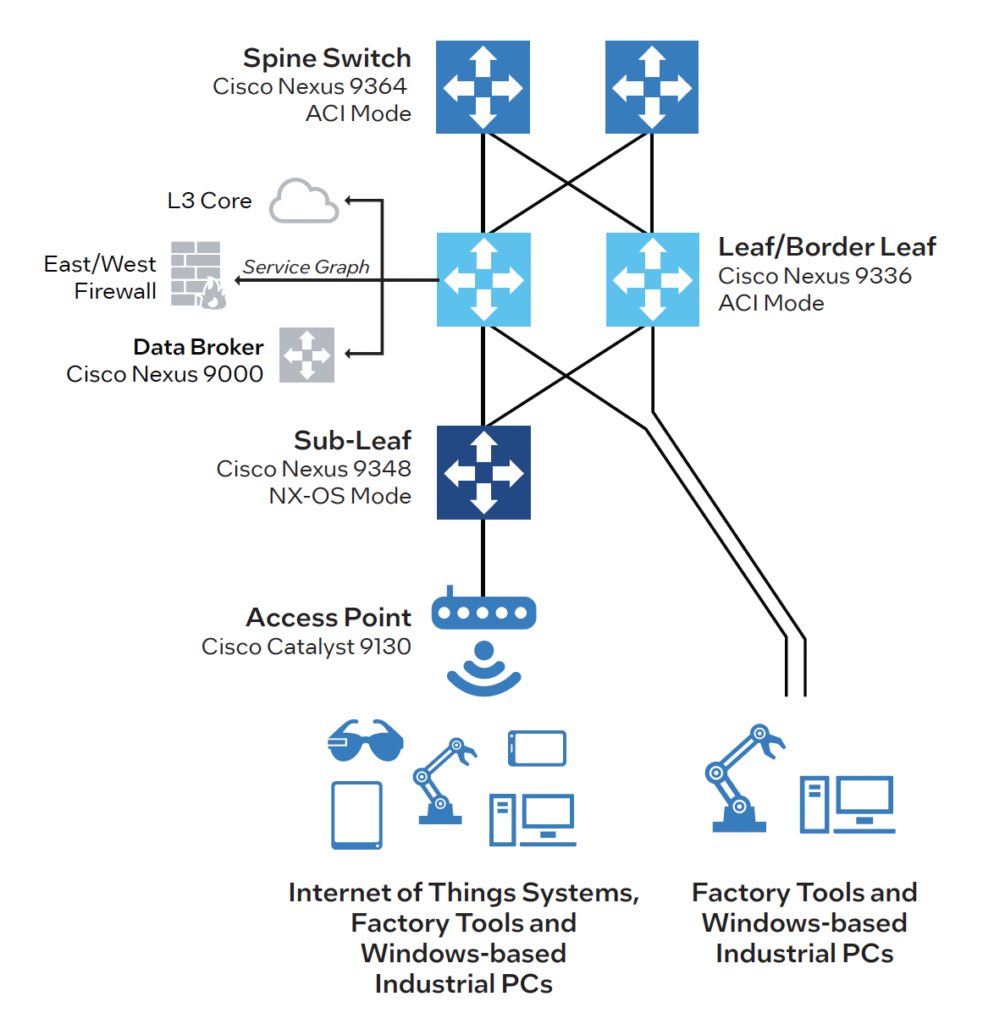

In collaboration with Cisco, we determined to undertake Cisco’s Software Centric Infrastructure (ACI). This allowed us to maneuver to a extra fashionable, streamlined method for controlling visitors flows utilizing Endpoint Teams (EPGs) and Contracts. This new mannequin allows us to create granular safety insurance policies and apply them to particular instrument units, exactly controlling information movement between them. Whereas our preliminary thought was to implement ACI all over the place, overlaying each the manufacturing unit flooring and our information facilities, via open, clear discussions with Cisco we pivoted towards a hybrid mannequin: ACI now manages the intricate visitors inside the manufacturing unit flooring, securing our 2,700+ VLANs and 1,100+ instrument sorts, whereas firewalls deal with the East-West[2] visitors between the info heart and the manufacturing unit flooring, offering crucial deep packet inspection.

Crucially, the migration of those 1000’s of VLANs was a monumental job, and that is the place Cisco CX stepped in, offering the automation experience to characterize our advanced visitors flows, changing them into the EPGs and contracts important for our new ACI atmosphere.

Deploying with Confidence: The Important Position of Answer Validation Providers

Given the unforgiving nature of our factories, once we deploy new capabilities in a manufacturing unit, we wish to guarantee issues will work proper the primary time round. Because of this Cisco’s Answer Validation Providers (which can be found by way of Skilled Providers) have been crucial for us, permitting rigorous testing of all important new capabilities earlier than they went dwell.

Cisco constructed a lab that mirrors our manufacturing unit atmosphere, with configurations and community part integrations that have been a real reflection of our manufacturing setup, tuned over years to remain in sync. This pre-deployment validation gave us a excessive diploma of confidence that any potential points had been recognized and resolved within the lab, making certain our manufacturing vegetation remained safe and operational.

From Oregon to the World: Scaling to our World Community

Whereas having an award-winning deployment is a giant win, this challenge is a multi-year funding for us. Our Oregon facility – the place this deployment occurred – is the primary hub the place all first-kind installs are carried out earlier than being rolled out to the remainder of the factories worldwide.

We’re at the moment deploying ACI throughout all our factories worldwide, which additionally entails uplifting our change and routing platforms to the newest Cisco Nexus expertise.

Automation can be a key enabler, and Cisco CX helps us with that. In Oregon, CX introduced in consultants to do the characterization and assist us automate our workflow – one thing we didn’t have the bandwidth or the sources to do ourselves. What actually impressed me was that they took the time to grasp the issue – and even reshape the character of their assist in response to our wants. They didn’t simply present the expertise framework; they supported us programmatically too, which gave us the momentum to maneuver ahead.

Securing the Way forward for Chip Manufacturing within the West

Zooming out, the broader context for our efforts is the surging international demand for chips, largely fueled by the explosion of AI.

In my opinion, it’s crucial to strengthen our provide chains within the West – the pendulum has moved too far offshore growing dangers, with necessary safety implications. Intel has been a powerful advocate and investor in addressing these considerations, constructing new wafer fabrication services and increasing present ones within the US and Europe.

Nevertheless, with unhealthy actors more and more focusing on crucial infrastructure, the business should undertake a world-class safety posture. This implies steady modernization of our expertise infrastructure, implementing sturdy “protection in depth” methods – like our ACI challenge – to guard these very important belongings and guarantee uninterrupted manufacturing towards subtle threats.

Learn extra:

IT@Intel Whitepaper: Reworking Industrial Manufacturing with Software program-Outlined Networking

[1] Lab robes

[2] East-West visitors refers to community communication that happens laterally between servers, purposes, or gadgets inside the similar information heart or, on this case, manufacturing unit community.