Surging demand for synthetic intelligence (AI) and computing energy is driving knowledge facilities to ramp up their cooling capabilities.

McKinsey & Firm estimates that international demand for knowledge centre capability may develop by 19–20% yearly via 2030, pushing yearly consumption to between 171 and 219 gigawatts by the top of the last decade.

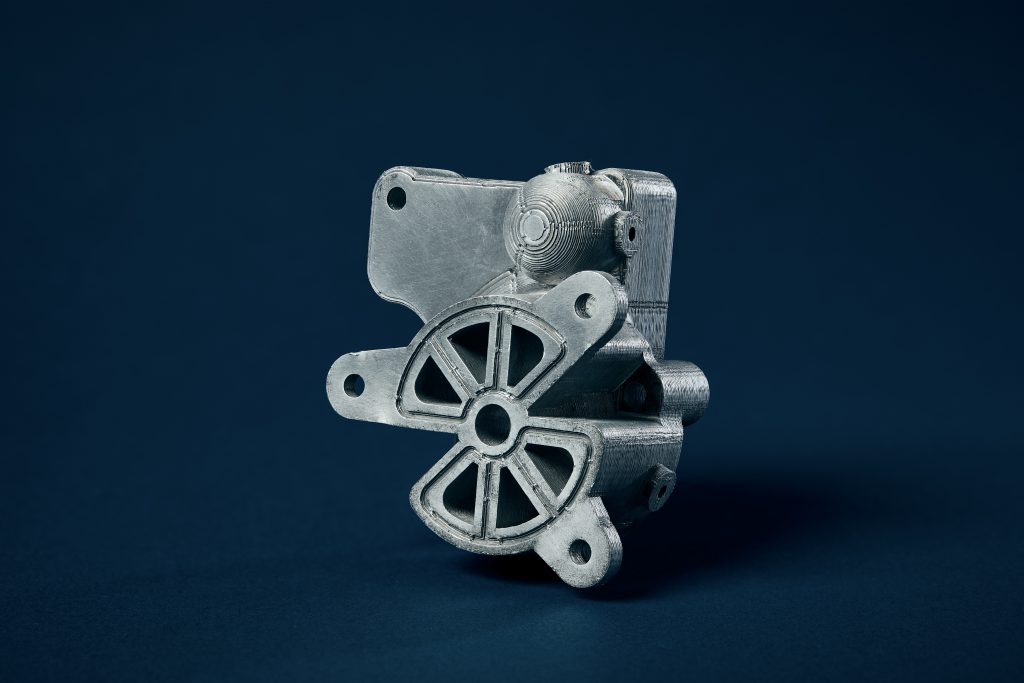

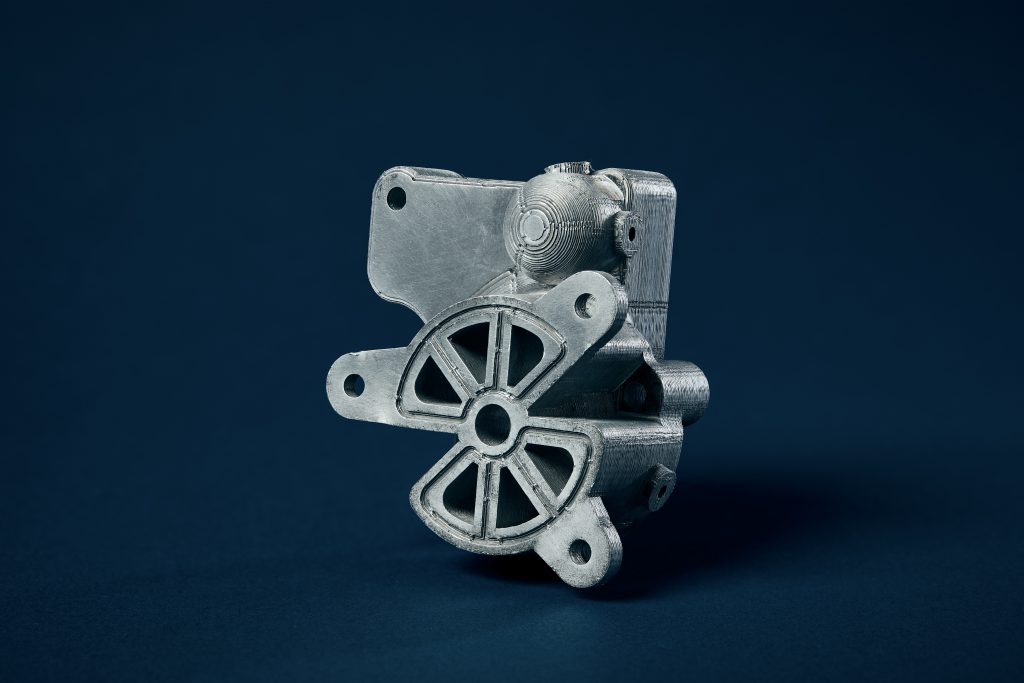

Burlington-based Alloy Enterprises is assembly this rising demand with its American-made direct liquid cooling (DLC) chilly plates. These are designed to enhance GPU server rack effectivity, decreasing energy consumption by 21% and reducing pumping strain by an element of 4.

Entry extra professional insights at Additive Manufacturing Benefit: Vitality on September seventeenth. Reserve your free ticket now.

Alloy makes use of its proprietary steel additive manufacturing know-how, Stack Forging, to provide its units. This course of fuses layers of laser-cut aluminum and copper sheets into totally dense, high-performance components. In response to CEO Ali Forsyth, the strategy can create inner microchannels as small as 50 µm.

In a latest interview with 3D Printing Business, the Harvard College graduate estimated the 2024 serviceable addressable marketplace for GPU and manifold cooling at $1.1 billion, with a projected CAGR of 36%. Forsyth referred to as Stack Forging the perfect additive course of to fulfill hovering demand for knowledge middle cooling and revealed that Alloy is scaling its DLC resolution for mass manufacturing.

The corporate can produce 15,000 elements per thirty days with a 92% half yield. It makes use of aluminum that prices lower than $10 per kilogram, 20 instances cheaper than the powder-based 6061 aluminum utilized in laser powder mattress fusion (LPBF). Alloy has additionally built-in copper into its DLC resolution, growing thermal efficiency by roughly 30% in comparison with aluminum alone.

In the end, Forsyth emphasised the pressing want to chop the carbon emissions of knowledge facilities. She cited cleaner energy sources, like nuclear fusion, as key to averting the looming vitality disaster.

What’s Stack Forging?

Alloy Enterprises was based in early 2020. The corporate sought to develop a course of able to producing totally dense aluminum elements at larger throughput and decrease price than current steel 3D printing strategies.

“Our objective was simply to maneuver numerous steel via the machine and make high-performance elements,” Forsyth defined. “We believed that if we may create a producing course of that might try this, we may open up some newer market alternatives at larger volumes for sequence manufacturing.”

Forsyth’s firm now runs two shifts on the manufacturing ground, with some tools working 24/7. Over the previous two years, Alloy has skilled rising demand for superior thermal administration, pushed by clients looking for higher cooling for high-power units. Whereas preliminary curiosity got here from photonics and protection primes, it shortly expanded to semiconductor tools, knowledge facilities, and GPU cooling.

At the moment, the agency focuses on thermal administration {hardware}, particularly for knowledge middle server racks. It ships licensed elements to fifteen clients worldwide, together with a few of the “largest people within the trade,” Forsyth defined. Alloy’s major purchasers are server rack OEMs, hyperscalers, and chip producers.

On the core of Alloy’s know-how is its proprietary Stack Forging course of. This begins with skinny sheets of 6061 aluminum alloy or C110 copper, sometimes 350 to 400 µm thick. Every layer is laser-cut to outline the half’s geometry, together with intricate inner channels and multi-part nesting.

An inhibition agent, functioning like a mould launch, is then selectively printed onto the floor earlier than the layers are stacked and positioned right into a “Bond Machine.” This supplies warmth and strain in a managed atmosphere to create strong, totally dense elements. Lastly, the components are heat-treated to reinforce power and hardness.

Notably, these monolithic elements are leak-free, an important benefit when utilizing liquid to chill GPU racks that may be price tens of millions of {dollars}. “Lowering the chance of leaking on this actually costly and worthwhile {hardware} is totally central,” Forsyth stated.

One other key differentiator is Alloy’s precision and skill to create enclosed, intricate geometries that legacy manufacturing strategies can’t obtain. Finer microchannels ship larger thermal efficiency, a important consider optimizing high-powered electronics.

Forsyth emphasised that stack forging outperforms different steel additive manufacturing processes. She said that the smallest comparable channels made utilizing LPBF can attain round 300 µm, whereas stack forging can obtain 50 µm, “and we’re pushing all the way down to 10 µm.” Moreover, as a result of Alloy’s technique avoids melting, sintering, or fusing, the ensuing elements are freed from porosity and ship superior mechanical power, Forsyth added.

Stack Forging additionally gives vital benefits in printing velocity and throughput. In response to Forsyth, the method delivers 9 instances the throughput per laser in comparison with LPBF. On the supplies aspect, Alloy’s aluminum sheets are 20 instances cheaper than powder-based 6061, whereas being considerably simpler to deal with.

Not like steel powders, which require energy-intensive atomization and sophisticated post-processing, Alloy’s sheet-based feedstock has a decrease carbon footprint and eliminates the danger of trapped powder in slim inner channels.

In the meantime, waste materials, principally assist sections, could be simply collected and recycled. “We’ve designed our course of round reusability,” Forsyth added. “Each aluminum and copper scrap could be remelted and turned again into sheet with minimal waste.”

Enhancing thermal administration for knowledge facilities

Holding knowledge facilities cool is an pressing problem. As digital infrastructure expands, servers are processing ever-larger volumes of knowledge and emitting huge quantities of warmth. AI-ready amenities are particularly power-hungry, pushed by the excessive common energy densities of their server racks.

In response to McKinsey, common energy densities greater than doubled from 8 kW in 2022 to 17 kW in 2024, and are anticipated to succeed in 30 kW by 2027. Coaching fashions like OpenAI’s ChatGPT can require over 80 kW per rack. Throughout this yr’s GTC AI convention, NVIDIA’s CEO, Jensen Huang, revealed his firm’s new NVL576 rack, which is able to utilizing as much as 600 kW of energy.

“Chipmakers are producing bigger, hotter processors, making environment friendly cooling a important concern for knowledge centres,” stated Forsyth. She famous that cooling these methods can devour greater than 20% of a facility’s complete energy, making thermal effectivity invaluable.

Alloy Enterprises goals to deal with these challenges with its direct liquid cooling (DLC) resolution. The chilly plates characteristic intricate inner microcapillaries that improve cooling effectivity. In response to the corporate, these complicated architectures scale back thermal resistance by as much as 50% and enhance Energy Utilization Effectiveness (PUE) by 18%.

The 3D printed elements additionally ship an exceptionally low strain drop, which Forsyth revealed is 4 instances decrease than the closest competitor. This reduces pumping resistance and improves liquid stream price, that means much less vitality is required to flow into cooling fluid round knowledge middle racks.

Crucially, improved thermal efficiency permits knowledge facilities to chill extra highly effective chips utilizing higher-temperature water, which is usually 44°C. “You need to have the ability to flow into hotter water all through your facility,” Forsyth defined. This, in flip, permits dry chillers to discharge warmth outdoors, sidestepping the necessity for energy-intensive refrigerated air-con methods. Forsyth described this as “completely important for energy financial savings.”

Forsyth argued that “100% liquid cooling is the best way ahead,” eliminating the necessity for cumbersome, energy-intensive warmth sinks and followers required for air-based cooling. The corporate’s liquid-focused elements additionally allow larger cooling density, permitting rack builders to pack extra electronics.

Along with GPUs, these peripheral elements embody reminiscence, SSD exhausting drives, energy provides, QSFP transceivers, and Community Interface Playing cards (NICs). “We have now numerous clients searching for half consolidation, serving to to chill multiple merchandise at a time with a single cooling plate,” defined Forsyth.

In modeled situations for 2030, Alloy’s know-how reduces complete energy use in a 75 MW knowledge middle by 21%, in comparison with the following most suitable choice. “It’s extremely exceptional how a lot energy could be saved with larger efficiency cooling elements,” Forsyth added.

Alloy Enterprises started producing 3D printed GPU cooling units utilizing 6061 aluminum sheet. Earlier this yr, it used the identical materials to create a liquid chilly plate for NVIDIA’s H100 PCIe card.

This high-performance knowledge middle GPU is designed to speed up AI and superior computing. Alloy developed the cooling plate utilizing topology optimization design software program from nTop. This course of allowed the workforce to optimize the system’s geometry utilizing simulation knowledge, together with warmth flux, fluid stream, and structural constraints.

In latest months, Alloy has moved past aluminum, unveiling its copper DLC resolution in June. By utilizing C110 copper, the corporate has reportedly improved cooling effectivity by about 30% in comparison with aluminum. The fabric additionally meets ASHRAE chemical compatibility requirements, decreasing the danger of corrosion, degradation, and leaks.

Mass manufacturing with steel 3D printing

As demand for AI compute surges, Alloy is ramping up manufacturing to maintain tempo. Its present facility can produce 15,000 elements per thirty days. Capability could be expanded by including further modular Stack Forging cells to the manufacturing line.

“The scalability of Stack Forging was core to the event of the know-how,” defined Forsyth, who’s focusing on “mass manufacturing” of her firm’s DLC units. “We have now no drawback servicing clients that want tens of 1000’s of elements yearly,” she revealed.

That scale issues, as the marketplace for knowledge middle cooling continues to surge. “The demand for compute is skyrocketing. The demand for energy to gas that compute is skyrocketing. And the demand for cooling elements is correct alongside it,” Forsyth added.

The CEO, previously an Engineering Supervisor at 3D printer OEM Desktop Steel, stated she plans to scale output to fulfill rising buyer demand. The main focus is squarely on next-generation knowledge facilities, with no plans to pursue retrofits of current amenities.

I requested Forsyth why Alloy opts to provide DLC elements in-house fairly than promote its Stack Forging machines to clients. She cited the numerous challenges of coaching clients to reliably function 3D printing methods and design components for additive manufacturing.

“We had a selection between the primary 5 machines at 5 buyer websites, or the primary 5 machines in our facility run by our workers,” stated Forsyth. “So as to guarantee reliability and high quality, we felt the perfect path was to place our cash the place our mouth was.”

This in-house strategy is paying off. Alloy has steadily improved tools effectivity lately, reaching a 92% half yield in Might 2025, a formidable benchmark in industrial 3D printing. “I’m extremely happy with the engineering and manufacturing groups for having achieved that milestone,” Forsyth stated.

The way forward for 3D printing for GPU cooling

Trying to the longer term, Forsyth acknowledged that energy availability for knowledge facilities just isn’t limitless, making improved thermal efficiencies important. “Any kilowatt it can save you can be utilized to generate extra tokens or run extra computations,” Forsyth stated. “That interprets into larger top-line income or decreased CO₂ emissions.”

Certainly, the carbon footprint of knowledge facilities is dealing with rising scrutiny amid tightening environmental laws and emissions targets. In response to the Worldwide Vitality Company (IEA), knowledge facilities consumed roughly 415 Terawatt-hours in 2024, roughly 1.5% of worldwide electrical energy use. The IEA estimates that, to attain its Internet Zero targets, knowledge‑middle emissions should halve by 2030.

Lots of Alloy’s clients, notably hyperscalers, have dedicated to reducing their carbon footprints. For Forsyth, DLC’s effectivity positive aspects are key to assembly these objectives. She highlighted its capability to ship extra compute per kilowatt and run on uncooled 44°C water important. She additionally famous that Stack Forging’s sheet-based feedstock generates considerably much less CO₂ than the steel powder utilized in LPBF, whereas being far simpler to recycle and reuse.

The tech CEO additionally urged a shift towards cleaner vitality to energy knowledge facilities. She highlighted Google’s latest settlement to purchase 200 megawatts of electrical energy from ARC, a compact nuclear fusion plant being developed by MIT spin-off Commonwealth Fusion Methods (CFS). Positioned in Chesterfield County, Virginia, ARC goals to ship clear vitality by the early 2030s.

“I believe our complete society will profit from that,” exclaimed Forsyth. “If it’s knowledge facilities that push these improvements, then I’m okay with that, as a result of the entire world’s gonna want it.”

Registrations are actually open for Additive Manufacturing Benefit: Vitality on September seventeenth. Reserve your free ticket now.

Need to assist choose the winners of the 2025 3D Printing Business Awards? Register to affix the Professional Committee in the present day.

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

You may also observe us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals Alloy Enterprises’ copper chilly plates. Picture by way of Alloy Enterprises.

![[INTERVIEW] 3D Printing the Way forward for Information Middle Cooling at Alloy Enterprises [INTERVIEW] 3D Printing the Way forward for Information Middle Cooling at Alloy Enterprises](https://i1.wp.com/3dprintingindustry.com/wp-content/uploads/2025/08/Alloy-Enterprises-copper-cold-plates.-Photos-via-Alloy-Enterprises.jpeg?w=696&resize=696,0&ssl=1)