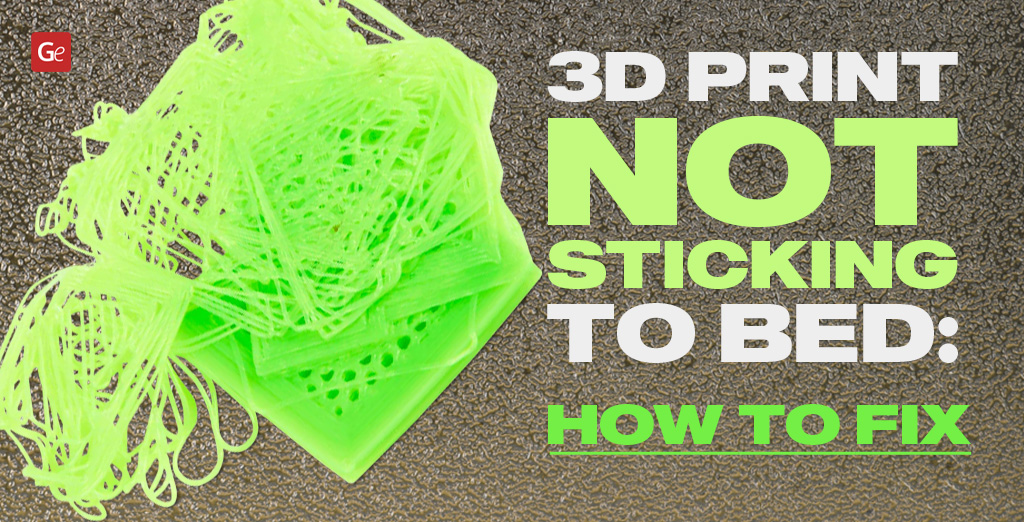

Newbies in 3D printing typically encounter a standard subject: a 3D print not sticking to the mattress. It may possibly occur while you recreate essentially the most spectacular 3D print objects and figures with ABS, PLA, and different kinds of filament. Fortunately, there are easy steps that may show you how to repair 3D printer mattress adhesion issues.

For the reason that first layers of any mannequin should adhere nicely to the 3D printer platform to make sure a profitable print, it’s important to observe your 3D printer mattress adhesion. Comply with Gambody’s 3D print troubleshooting tricks to keep away from such issues with filaments and make excellent masterpieces.

3D Printer Mattress Adhesion: What Is It?

Years in the past, hobbyists needed to take a number of steps to troubleshoot filament not sticking to mattress. From glue to leveling to controlling pace and temperature, it took some time to grasp the methods that helped obtain a beautiful consequence.

Immediately, lovers can store for excellent, user-friendly 3D printers for freshmen that include auto-leveling techniques, wonderful PEI bending beds that eradicate the necessity for tape and glue sticks, and different perks that had been solely a dream previously. Nonetheless, the problem of 3D printer mattress adhesion persists. It’s simply simpler to care for.

Mattress adhesion ensures your first layers of filament stick nicely to the platform, permitting your machine to extrude new layers on high and produce a stable print that’s steady, doesn’t ‘stroll round’ ruining the form or inflicting the ‘elephant foot’ impact, and received’t all of a sudden fall to the facet or trigger the venture to fail in another method.

The query is, what do you have to do with 3D print not sticking to mattress?

Learn additionally: 7 Working Options (How one can Take away a 3D Print from Mattress).

PLA Not Sticking to Mattress

When you learn every little thing about PLA filament, you’ll know that PLA mattress adhesion temperature is crucial to bear in mind when working with this 3D printing materials.

Whilst you can preserve your mattress chilly when working with PLA plastic, it’s nonetheless greatest to preheat it to roughly 40°C to 70°C (104°F to 158°F) to attain the perfect outcomes. Additionally, if you happen to can regulate your 3D printing settings, flip off the cooling fan or make it run slowly whereas your machine extrudes the primary two layers. After this, you possibly can pace up your fan to its full capability and revel in creating lovely PLA 3D prints.

ABS Not Sticking to Mattress

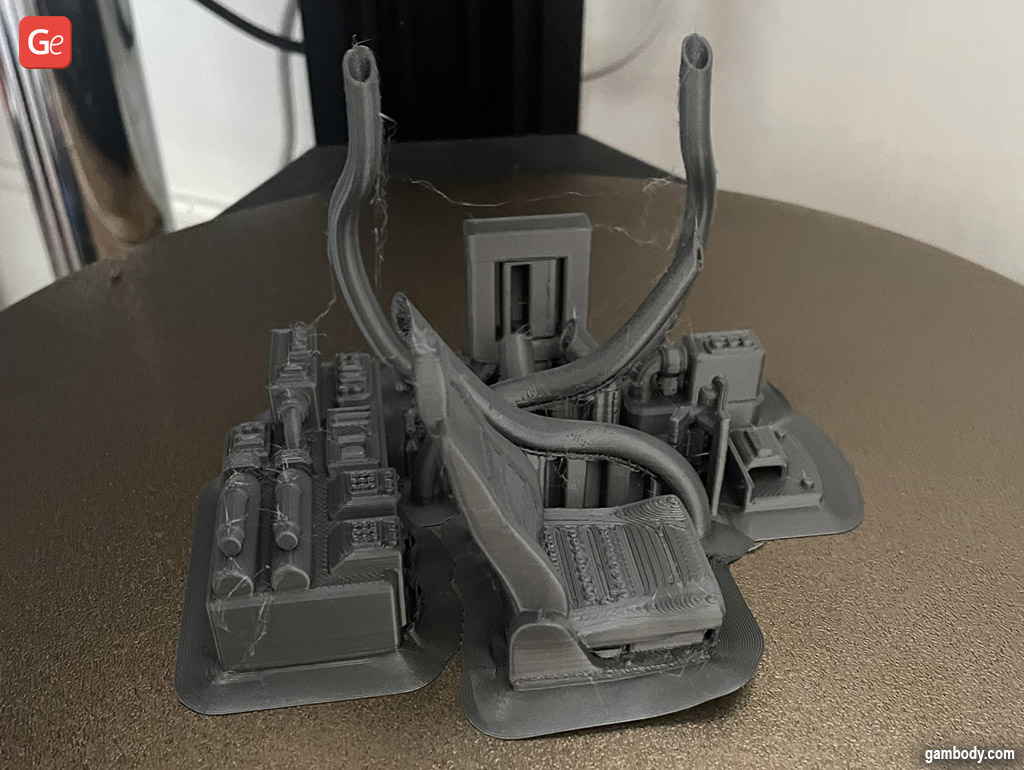

ABS will not be so simple as PLA. This filament requires extra settings and testing to make sure you fastened the issue of your prints not sticking to construct plate. ABS shrinks when it cools down. This plastic likes excessive temperatures, so it’s useful to think about the distinction between your nozzle and mattress temp when utilizing it.

Shrinking layers of plastic simply separate from the mattress, inflicting failed prints. Thus, if you happen to discover that your ABS materials first attaches however expertise the problem of the primary layer not sticking to mattress, regulate your temperature settings and guarantee your mattress maintains a high temperature of roughly 110°C (230°F) all through the venture. It’s greatest to check your ABS mattress adhesion temperature from 100°C to 120°C (212°F to 248°F) to find out what works greatest on your model.

Learn additionally: Greatest Star Trek 3D Printing Fashions.

Why Is My Filament Not Sticking to Mattress?

A number of components can affect the adhesion of your print to the mattress. Typically, the mattress leveling wants consideration. Typically, you have to monitor the temperature of your platform. Typically, it’s important to regulate your nozzle distance from the mattress.

Let’s look nearer at each potential subject and find out how to repair these 3D printer mattress adhesion issues.

Mattress Leveling for Higher Adhesion

Fashionable inexpensive 3D printers typically include an auto-leveling system. It means you now not have to regulate your printing platform, because the machine can do it routinely.

Nonetheless, some older variations might require guide changes utilizing knobs, screws, controls, or a bit of paper. Guarantee you’ve got a great flat platform that’s leveled as a result of if it’s unlevel, some areas may be far-off out of your nozzle whereas the opposite areas may be too shut, inflicting filament not sticking to mattress.

If the mattress is completely leveled (parallel to the nozzle), your print ought to adhere nicely.

Learn additionally: The Greatest Ender-3 Upgrades to Create Unbelievable 3D Prints (V2, Professional, Neo, V3 KE, S1, MAX).

Adjusting Mattress Temperature

As famous above, the platform temperature issues for several types of filament, together with PLA (much less) and ABS (extra). Guarantee you possibly can preheat your mattress to 40°C to 70°C (104°F to 158°F) if PLA doesn’t adhere nicely. Use a heated plate to work with ABS that requires greater temperatures from 100°C to 120°C (212°F to 248°F).

Depositing supplies that shrink at cool temperatures from a sizzling nozzle to a chilly construct plate is all the time a foul concept. Regulate the plastic you print with and regulate the print and mattress temp accordingly.

Nozzle Distance to Enhance 3D Printer Mattress Adhesion

When the extruder hotend has the right peak relative to your 3D printer mattress, the outcomes are considerably higher than when the nozzle distance is inaccurate.

The gap between your 3D printer nozzle and print mattress is named Z-offset. You need to fine-tune the Z-Axis G-Code offset by adjusting your settings or manually. Check by reducing your peak by 0.05 mm at a time to see how near the platform it ought to be, in order that the plastic is barely compressed in opposition to the mattress and yields good outcomes.

Most filaments are 0.18mm thick, so regulate the nozzle distance incrementally to keep away from extreme modifications. Be sluggish and affected person.

Learn additionally: Cleansing 3D Printer Nozzles at Residence (Easy Guides).

Experiment with Printing Pace

Plastics require a while to bond securely to your mattress. That is particularly vital for the primary few layers of your extremely detailed 3D print. Quick speeds may end up in 3D printer filament not sticking to mattress and resulting in a failed venture.

What are you able to do to troubleshoot this subject? Begin with decrease speeds till you guarantee the primary layer has adhered nicely to the platform. Then pace up your machine and let different layers construct properly on high.

You need to use 3D printer slicer software program to regulate the printing speeds and be sure that the primary couple of layers are printed at a considerably slower charge than the remainder of the mannequin.

Glue or Tape?

Hobbyists who’ve an older sort of construct platform that’s not serving to with print adhesion, it’s a good suggestion to “assist” your first layers stick nicely with further supplies. Apply glue or tape to the floor earlier than you start 3D printing and assist your PLA, ABS, or different plastic adhere.

It’s possible you’ll must experiment with several types of tape, as ABS is understood to be suitable with Polyimide movie, whereas PLA is extra suitable with painter’s tape.

Uncover many nice concepts of 3D printed figures and fashions on Gambody market!

As for the kinds of glue which might be common within the 3D printing neighborhood, experiment with sprays (together with hairspray), glue sticks, and short-term glue manufacturers to seek out your working resolution.

In case your platform is roofed with particular materials that helps filaments adhere on their very own, care for it. Make sure the floor is clear of mud, filth, oil, grease, and filament particles earlier than beginning a brand new 3D initiatives concepts. You possibly can clear the mattress with rubbing alcohol or water (see what the producer suggests).

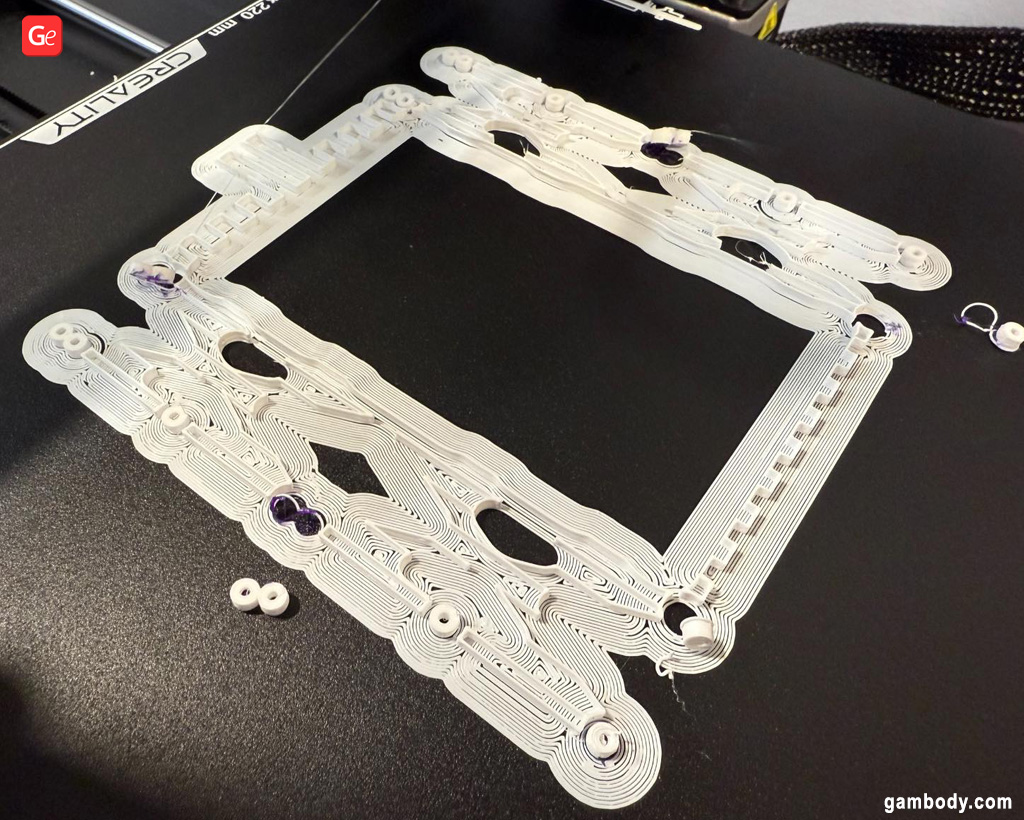

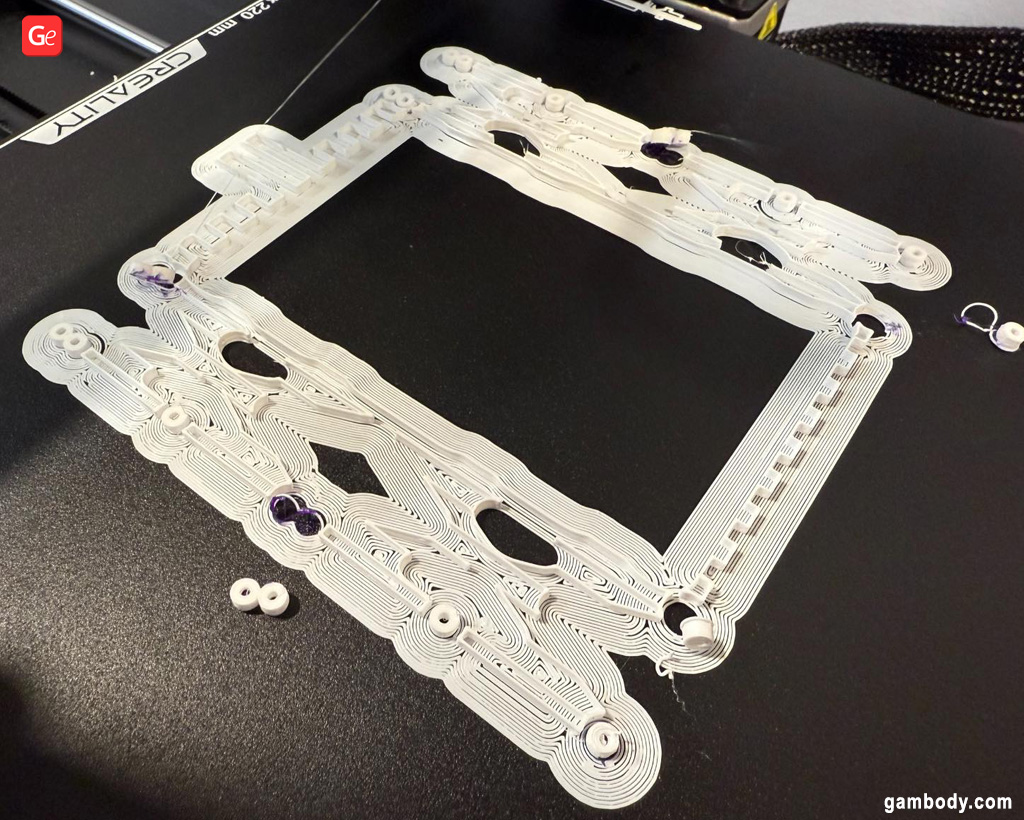

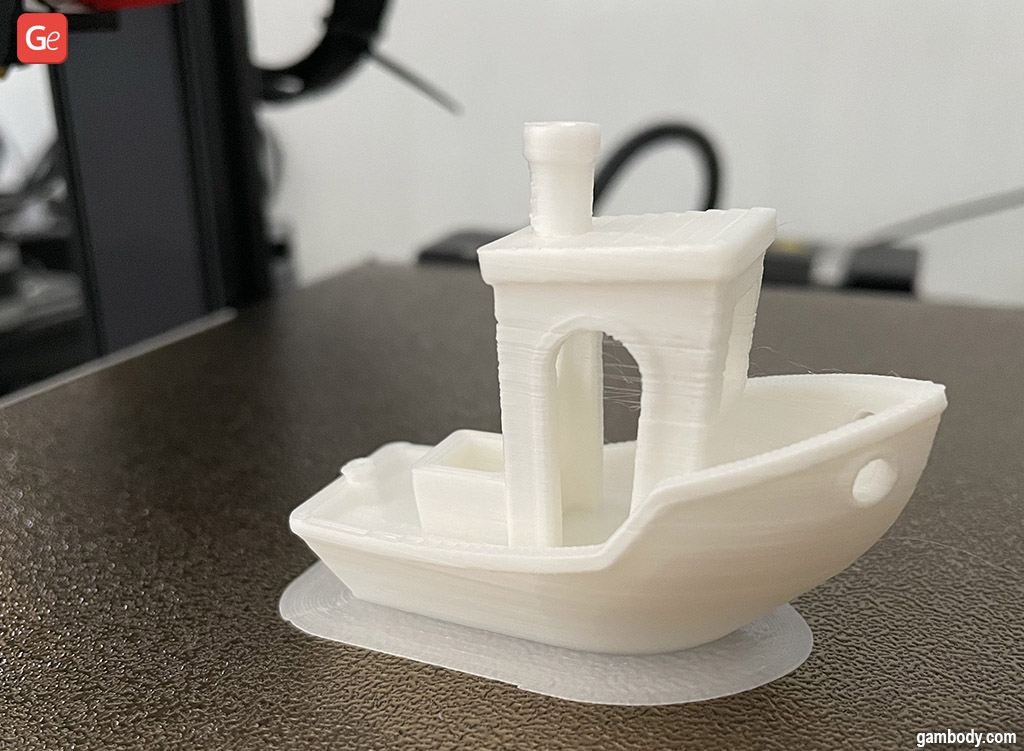

Resolution to Small Adhering Floor

Some components could also be too small to stick nicely to the mattress as a result of their restricted floor space. It’s doable to repair this subject utilizing your slicer. You may want so as to add an additional underlayer of a brim (referred to as a skirt) to extend the “sticking” floor of the primary layer and efficiently print your mannequin or determine.

Proceed experimenting and testing completely different plastic sorts to create extra unbelievable 3D printed initiatives, and also you’ll grasp extra fixing choices for widespread issues. You’ll be a 3D print troubleshooting guru very quickly and assist newbies from Gambody – 3D Printing Neighborhood on Fb, whose 3D printer filament not sticking to mattress, with recommendation and suggestions.

(Visited 13 instances, 1 visits right now)