Each main industrial period has been enabled by its supplies. Iron and metal outlined the mechanical age; Silicon is powering the digital one. Now, as manufacturing redefines itself across the wants of subsequent technology {hardware}, supplies are once more taking centre stage.

Throughout the additive manufacturing trade, supplies innovation in chemistry, formulation and processing are altering what’s potential. Excessive-temperature polymers rival metals in efficiency, bio-derived resins and recycled powders reduce carbon with out compromising energy. {Hardware} is evolving, nevertheless it’s the fabric that decides whether or not an concept strikes from CAD and turns into a product.

Subsequent technology {hardware} will demand versatile manufacturing strategies that each ship the precise components immediately and have the flexibleness to deal with no matter comes tomorrow.

Supplies are the limiting issue… and the chance

Since its inception additive manufacturing was constrained by materials efficiency. The components usually appeared spectacular, however most weren’t licensed or constant sufficient for true end-use functions. The breadth of supplies was no the place close to that for different established manufacturing applied sciences in each polymers and metals.

That’s altering. Right now, new formulations are reaching mechanical properties as soon as reserved for injection-moulded plastics and solid metals. Enhanced repeatability that makes them appropriate for manufacturing runs, not simply prototypes.

Producers are additionally starting to consider find out how to finest use what’s accessible as an alternative of demanding the ‘previous’ materials. Engineers now ask whether or not the accessible materials delivers the thermal, chemical or mechanical behaviour the applying calls for. Those that discover the precise match are gaining the power to localise manufacturing, simplify provide chains and ship tailor-made components on demand.

It’s one thing of a quiet revolution: much less seen than a brand new machine launch, however much more consequential.

Our method

Shapeways has lengthy been on the intersection of that shift. Our platform is constructed not solely on machines, however on the supplies that run via them. Each new addition to our portfolio is guided by a easy precept: permit extra challenges to be tackled with additive manufacturing.

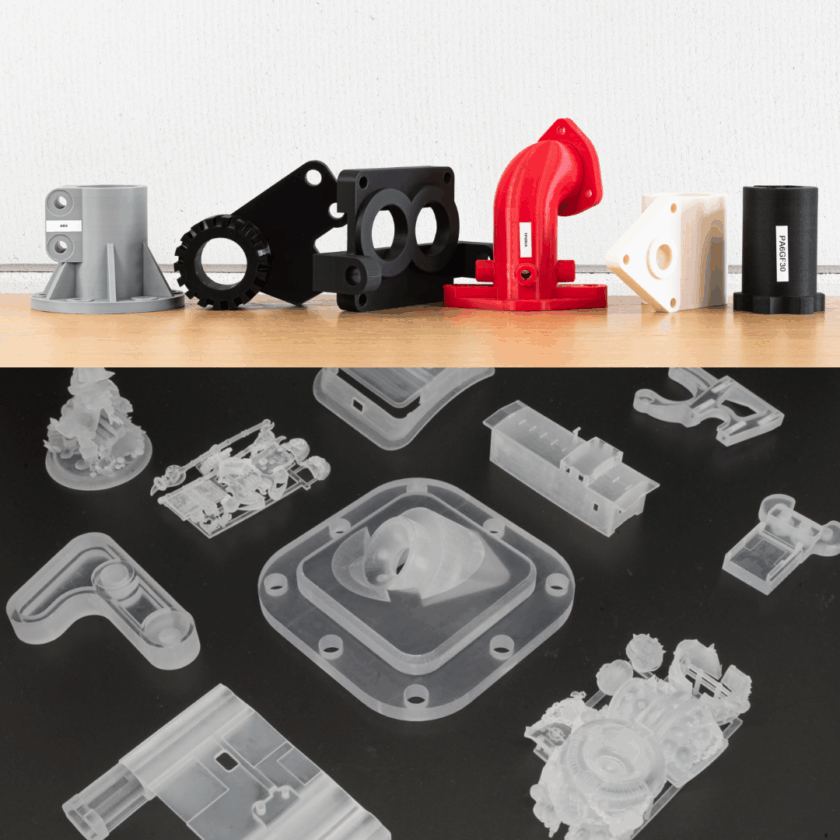

The newest enlargement introduces 4 industrial-grade supplies that proceed this development: SAF™ Polypropylene (PP), SAF™ Nylon 11 (PA11), Somos® Watershed Black, and Somos® Watershed XC 11122. Every arrives with distinct properties that open new doorways for designers and engineers.

Polypropylene brings one of many world’s commonest manufacturing polymers to the desk. It’s light-weight, fatigue-resistant, and chemically secure, splendid for parts that flex, seal or interface with liquids. Nylon 11 provides influence resistance and ductility, making it appropriate for protecting housings, versatile joints and structural components that must survive repeated loading.

The 2 Somos supplies prolong our attain into visible and optical territories. Watershed Black gives a high quality floor end and powerful dimensional accuracy for housings and enclosures the place aesthetics matter. Watershed XC pushes into transparency, enabling gentle guides, lenses, and fluidic units the place readability is practical, not ornamental.

Additive manufacturing supplies innovation is pushing design envelopes

The newest FDM additions (PPA-CF (carbon-fibre-reinforced polyphthalamide) and PPS-CF (carbon-fibre-reinforced polyphenylene sulfide)) proceed the supplies innovation momentum. Each are designed for demanding environments the place warmth, chemical substances and mechanical stress rule out commonplace polymers.

PPA-CF delivers energy, stiffness and dimensional stability at roughly half the load of aluminium, with warmth deflection temperatures (HDTs) as much as 188°C, making it splendid for structural brackets, housings and light-weight tooling. PPS-CF goes even additional, with HDTs round 252°C, UL 94 V-0 flame retardancy and glorious chemical resistance. This mixture is suited to automotive, aerospace, industrial and digital parts uncovered to harsh situations.

Every of those supplies represents greater than one other SKU in a listing — they’re constructing blocks for merchandise that may transfer rapidly and straight from digital idea to industrial manufacturing, with out compromise.

Why materials innovation defines the subsequent period

The large image is that the frontier of additive manufacturing not lies within the mechanics of printing, however within the supplies science of what’s being printed.

Because the resilience of world provide chains continues to be questioned, commerce obstacles erected and manufacturing more and more seen as a nationwide safety situation the power to provide stronger, lighter and extra localised components is changing into a aggressive differentiator. The businesses that thrive on this atmosphere will likely be people who embrace the palette of supplies accessible to them and embed them of their design logic.

That’s what Shapeways’ Subsequent Technology {Hardware} imaginative and prescient captures: a future the place efficiency and manufacturing agility converge, the place supplies innovation turns digital flexibility into bodily actuality.

The machines will preserve bettering in fact, nevertheless it’s the fabric that units the tempo. Each new formulation expands the boundaries of design and reshapes how merchandise are made, distributed and maintained. In that sense, supplies aren’t simply a part of the story of Subsequent Technology {Hardware}, they’re the muse of it.