The EU-funded InShaPe analysis mission has reported vital enhancements in laser-based powder mattress fusion of metals, reaching a sixfold improve in productiveness and lowering manufacturing prices by 50%. The three-year mission, coordinated by the Technical College of Munich, mixed AI-based beam shaping with multispectral imaging to handle widespread points in metallic additive manufacturing. The consortium included eleven companions from eight international locations and acquired €7.2 million in funding from the Horizon Europe framework programme.

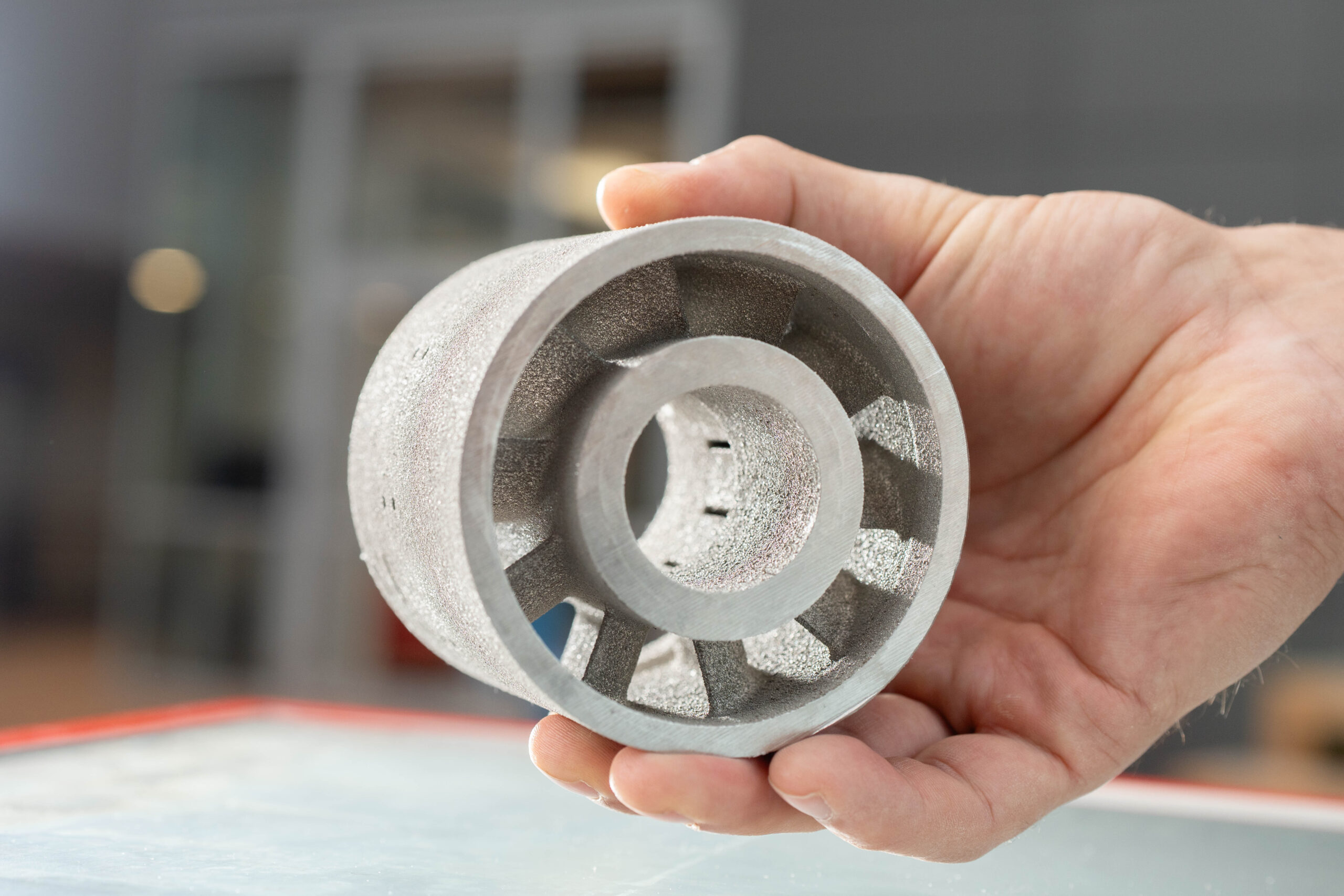

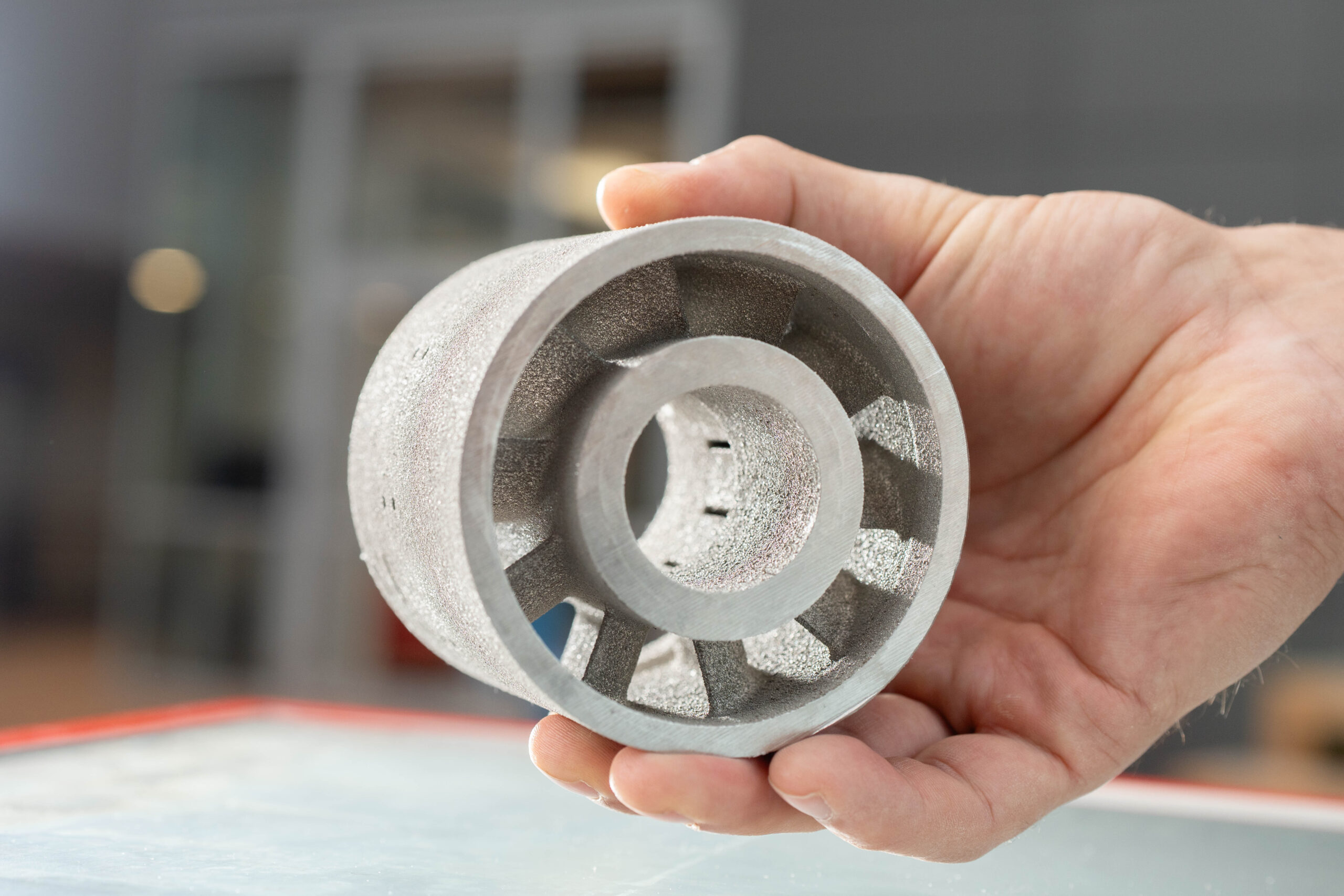

The analysis group demonstrated manufacturing charges of as much as 93.3 cm³/h utilizing Inconel 718, in comparison with the beginning charge of 15 cm³/h. The enhancements have been examined throughout 5 industrial purposes, together with parts for aerospace, vitality, and mechanical engineering sectors. These included an aerospace impeller, industrial fuel turbine components, house combustion chamber parts, a chainsaw motor cylinder head, and satellite tv for pc antenna parts.

The expertise facilities on clever beam shaping that adapts the laser profile to particular part geometry and supplies. Researchers discovered {that a} ring-shaped beam profile, quite than a conventional Gaussian beam, created extra steady soften zones and improved materials processing. This method decreased widespread defects akin to cracking, spatter, and condensate formation.

The multispectral imaging system displays the manufacturing course of in real-time throughout numerous wavelength ranges. This permits for early detection of thermal modifications within the soften pool, with information flowing instantly into course of administration programs. Beforehand production-stopping defects can now be corrected through the course of, lowering delays and waste.

“Educational and industrial curiosity in our work may be very excessive. We’re delighted that this expertise will quickly be utilized in industrial programs and drive advances in course of management, high quality assurance and software capabilities throughout a variety of sectors,” commented Prof. Katrin Wudy, the mission coordinator from the Technical College of Munich. The mission goals to advance the economic adoption of laser-based powder mattress fusion expertise, notably in aerospace, vitality, and automotive purposes.

Supply: bayfor.org