Added Scientific Ltd, a spinout from the College of Nottingham’s Centre for Additive Manufacturing (CfAM), has obtained strategic funding from additive manufacturing specialists Brent Stucker and David Leigh. The funding will speed up the enlargement and commercialization of the corporate’s product portfolio, specializing in its open 3D inkjet analysis platform, Jetforge.

Based by Professors Richard Hague, Chris Tuck, and Ricky Wildman from the College of Nottingham’s School of Engineering, Added Scientific gives analysis and supplies improvement companies for industrial and tutorial companions. The corporate’s administration crew attracts from probably the most completed additive manufacturing analysis teams in Europe, supported by a workers of engineers and scientists specializing in materials jetting, binder jetting, and photocurable 3D printing. Its contract R&D work allows distributors and end-users to refine supplies, deposition techniques, and course of management parameters throughout totally different additive platforms.

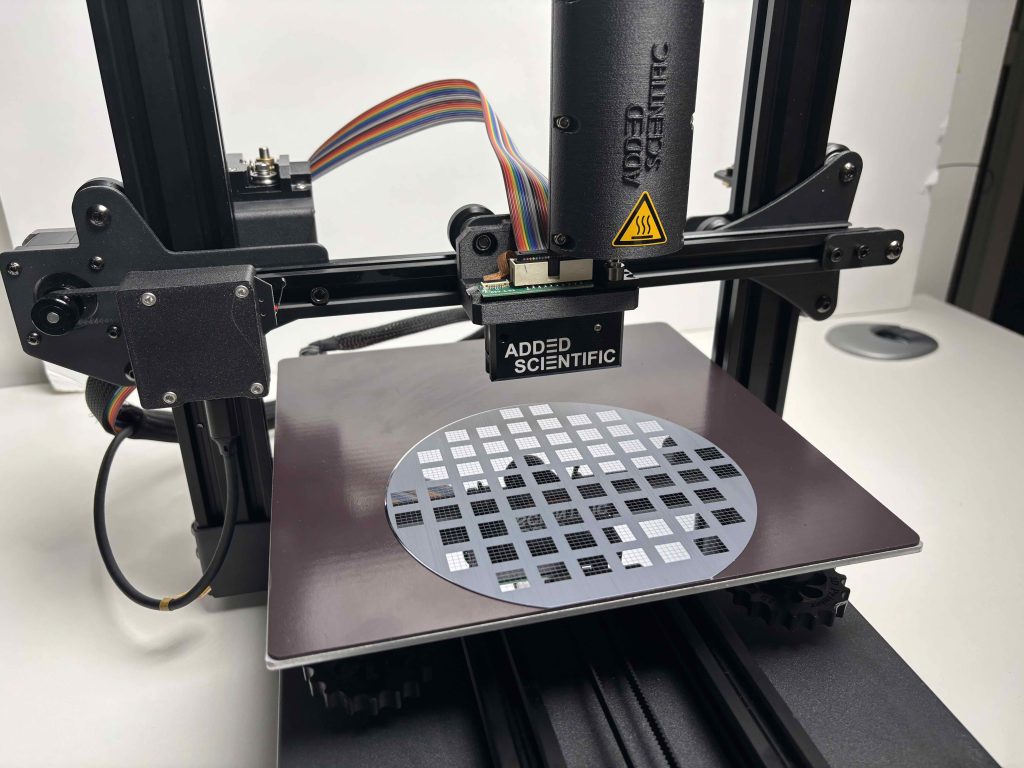

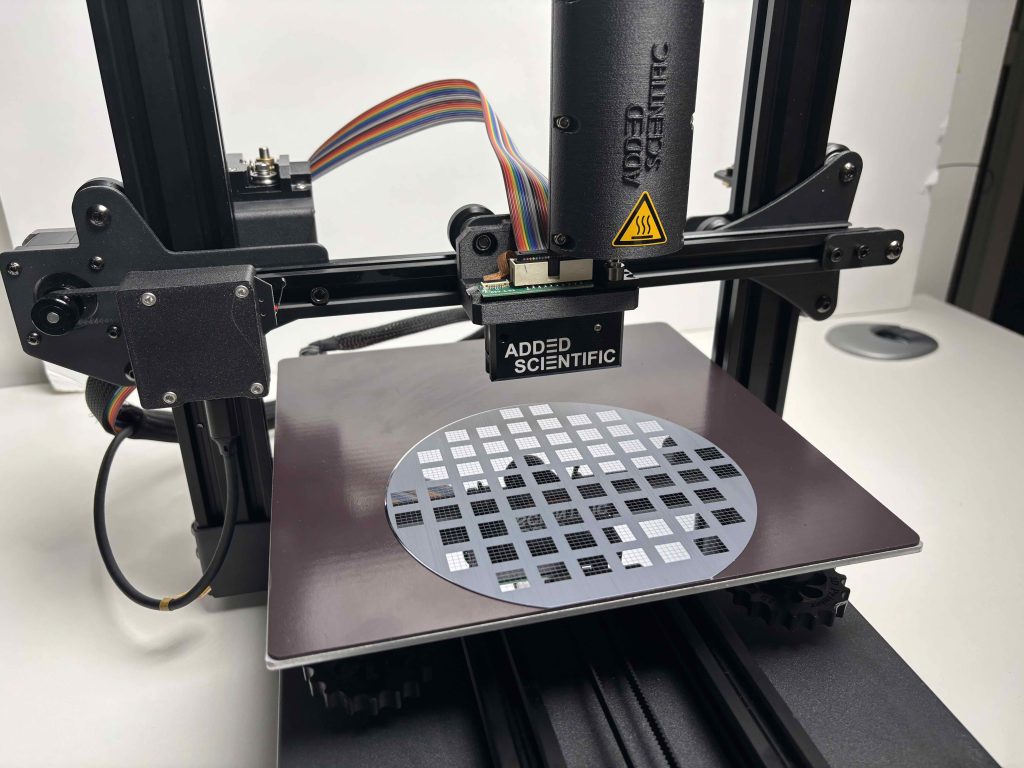

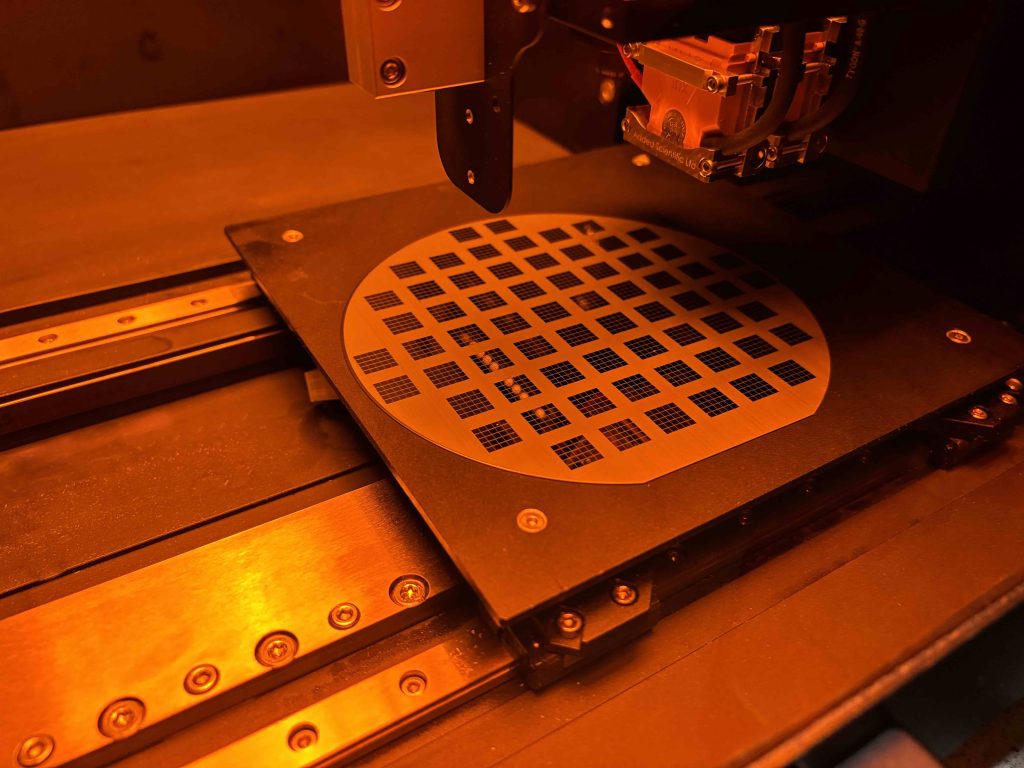

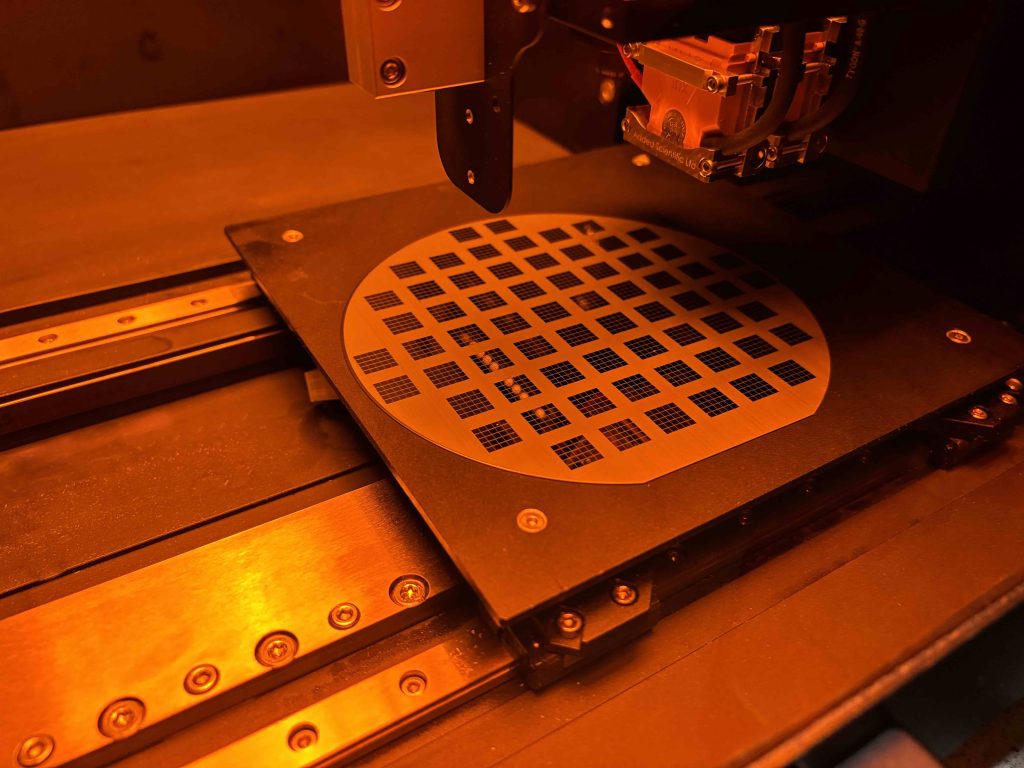

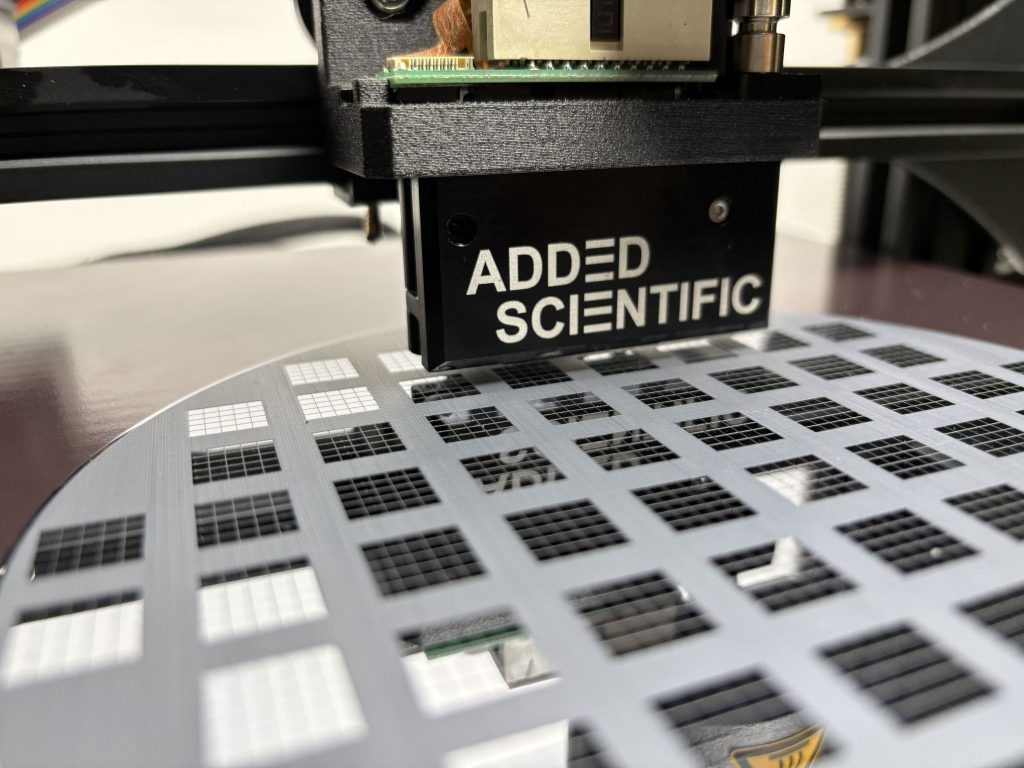

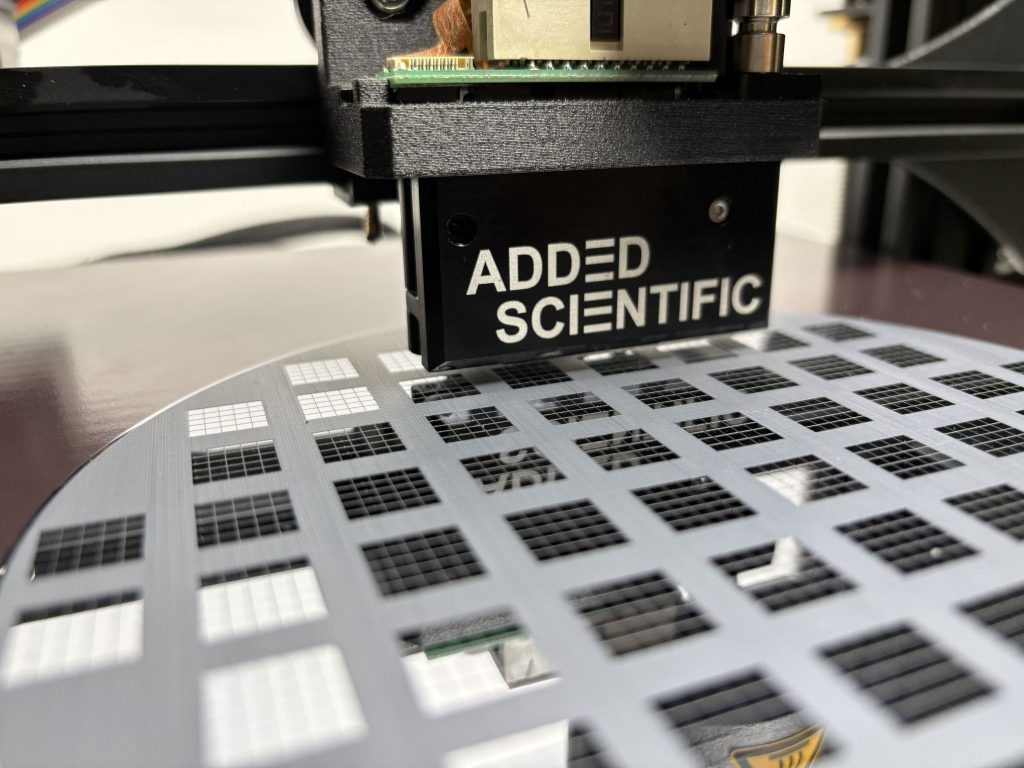

Jetforge, at the moment in its beta part, is an open, modular inkjet system designed to decrease the barrier to entry for supplies analysis and course of improvement. The benchtop platform accommodates a number of printheads, configurable {hardware}, and software program instruments that permit advanced printing methods. Customers can adapt the machine to particular fluid chemistries, advancing experimental work on polymers, ceramics, and useful supplies. Added Scientific additionally plans to broaden its providing to incorporate a spread of printers tailor-made to totally different merchandise, corresponding to electronics or structural elements.

Professor Hague, Director of CfAM and co-founder of Added Scientific, described the funding as a pivotal step within the firm’s transition from a contract analysis group to a full product supplier. “We’re delighted to obtain this funding from Brent and David as we transition from a contract analysis organisation to offering a full product providing,” Hague mentioned. “The Added Scientific crew is extraordinarily excited to collaborate with them as we develop our portfolio. This funding underscores the rising significance of AM in reworking industries, from aerospace to healthcare. The trade has grown at a gradual compound annual price of over 20% over the previous couple of years, and that momentum is barely set to proceed as entry to specialist expertise will increase.”

Trade experience joins the board

Brent Stucker, at the moment Chief Engineer for North America at Nikon SLM Options and Chief Know-how Strategist at Wohlers Associates, brings greater than three a long time of expertise in industrial additive manufacturing. He co-founded 3DSIM, a simulation software program firm acquired by Ansys, and has been instrumental in creating industrial requirements for metallic 3D printing.

David Leigh, founding father of Harvest Applied sciences, established one of many first licensed AM service bureaus producing flight-qualified aerospace components. Following Harvest’s acquisition by Stratasys, Leigh held senior management roles at 3D Techniques and EOS, contributing to the worldwide enlargement of polymer and metallic additive manufacturing applied sciences.

Each buyers will be part of Added Scientific’s Board of Administrators to supply strategic oversight and technical route as the corporate prepares to commercialize Jetforge and develop its product vary. Leigh mentioned, “Decreasing the barrier to entry for supplies improvement is essential to unlocking the subsequent wave of innovation in additive manufacturing. By making superior instruments extra accessible, Added Scientific is enabling a broader vary of researchers and builders to contribute to the sphere.”

Stucker emphasised the significance of accelerating supplies analysis. “The acceleration of supplies improvement is among the most essential challenges our trade faces,” he mentioned. “Added Scientific’s platform not solely has the potential to handle this head-on, but in addition to unlock new purposes and drive significant progress in additive manufacturing.”

Tutorial basis and industrial trajectory

Added Scientific’s basis inside CfAM ties it to certainly one of Europe’s main facilities for additive manufacturing innovation. CfAM’s work in multi-material printing, useful photopolymer chemistry, and electronics integration has positioned it as a reference level for industrial collaboration in next-generation 3D printing. Constructing on this basis, the spinout bridges laboratory analysis and industrial deployment, serving to companions speed up supplies and course of validation.

World additive manufacturing has maintained an annual development price above 20%, with robust demand from aerospace, protection, healthcare, and automotive industries. Materials qualification stays a serious bottleneck, and modular analysis techniques corresponding to Jetforge might present sooner experimentation cycles, enabling laboratories and producers to judge new supplies and printing methods extra effectively.

Added Scientific intends to make use of the brand new funding to advance Jetforge from beta testing to industrial availability. Plans embody increasing suitable printhead choices, integrating superior management options, and refining course of improvement instruments. Future purposes underneath analysis embody conductive inks, photocurable resins, and high-performance composites, supporting the corporate’s mission to make supplies innovation in additive manufacturing extra accessible and reproducible.

Assist form the 2025 3D Printing Trade Awards. Join the 3DPI Professional Committee in the present day.

Are you constructing the subsequent massive factor in 3D printing? Be part of the 3D Printing Trade Begin-up of the Yr competitors and develop your attain.

Subscribe to the 3D Printing Trade publication to remain up to date with the most recent information and insights.

Featured picture exhibits Shut-up of the Jetforge printhead meeting throughout a deposition check. Picture by way of Added Scientific.