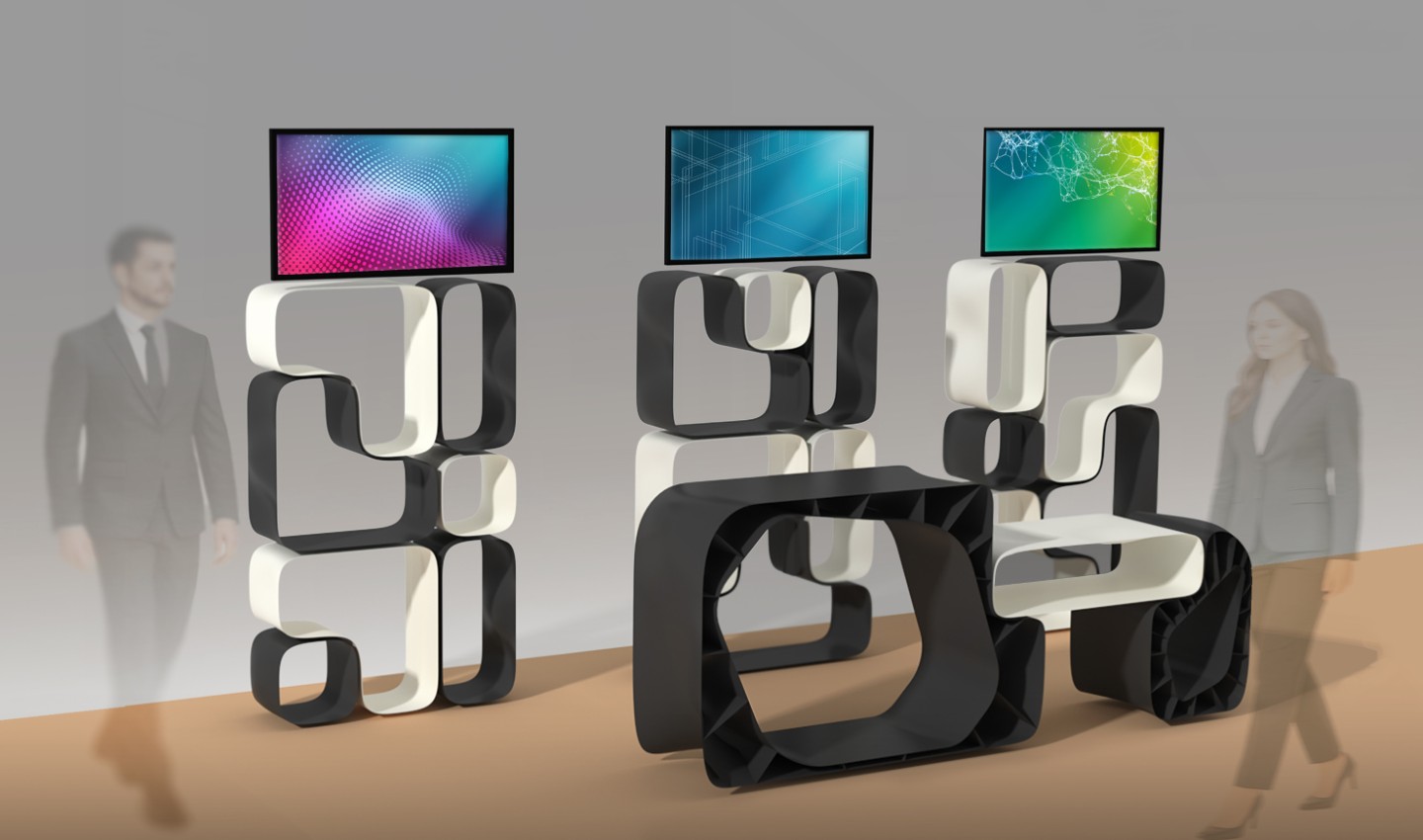

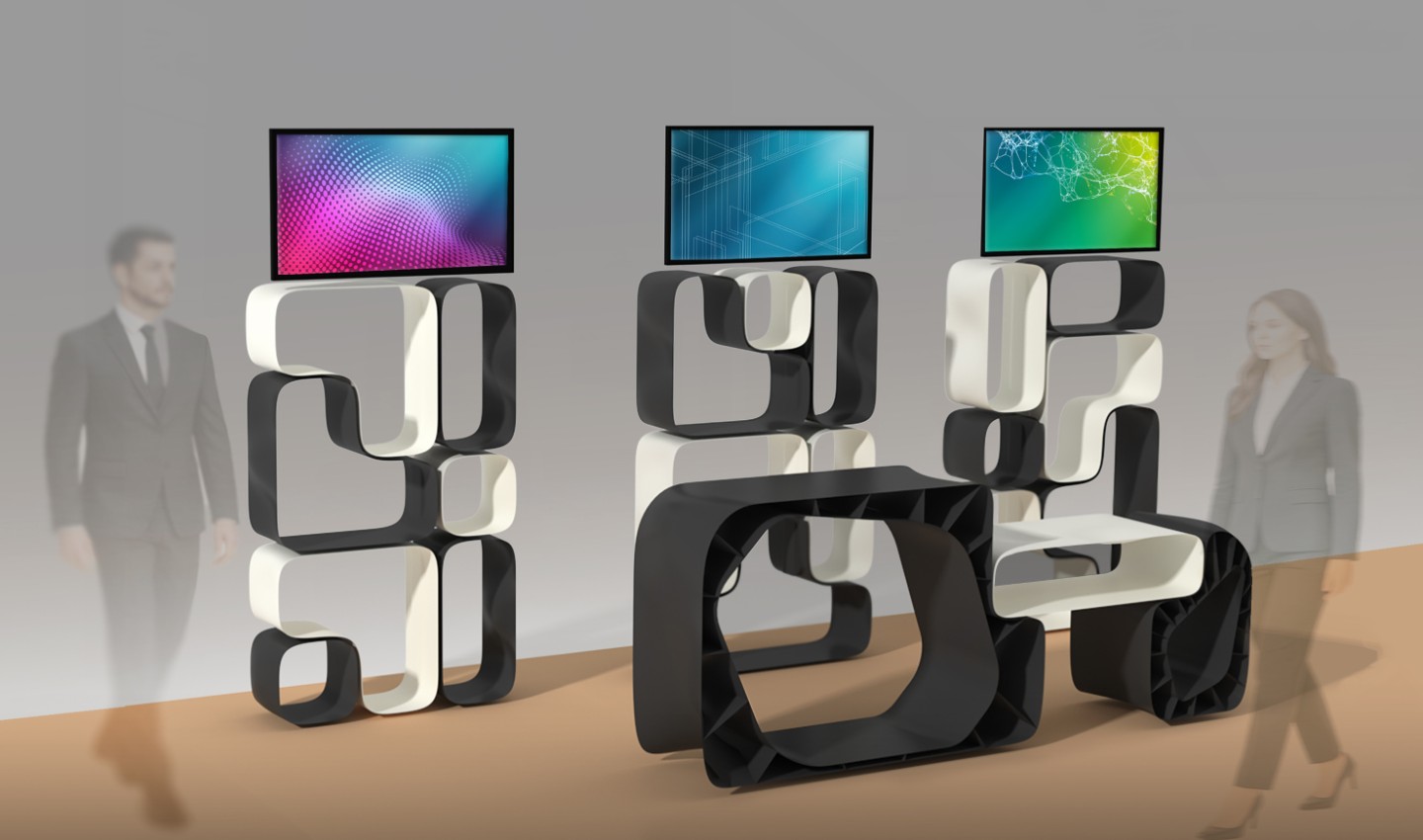

Fraunhofer IWU will current advances in laser powder mattress fusion know-how and sustainable exhibition design at Formnext 2025 in Frankfurt, November 18-21. The analysis institute’s sales space will characteristic a totally 3D-printed construction comprised of biodegradable plastic and recyclable polypropylene, which shall be reassembled and reused after the occasion.

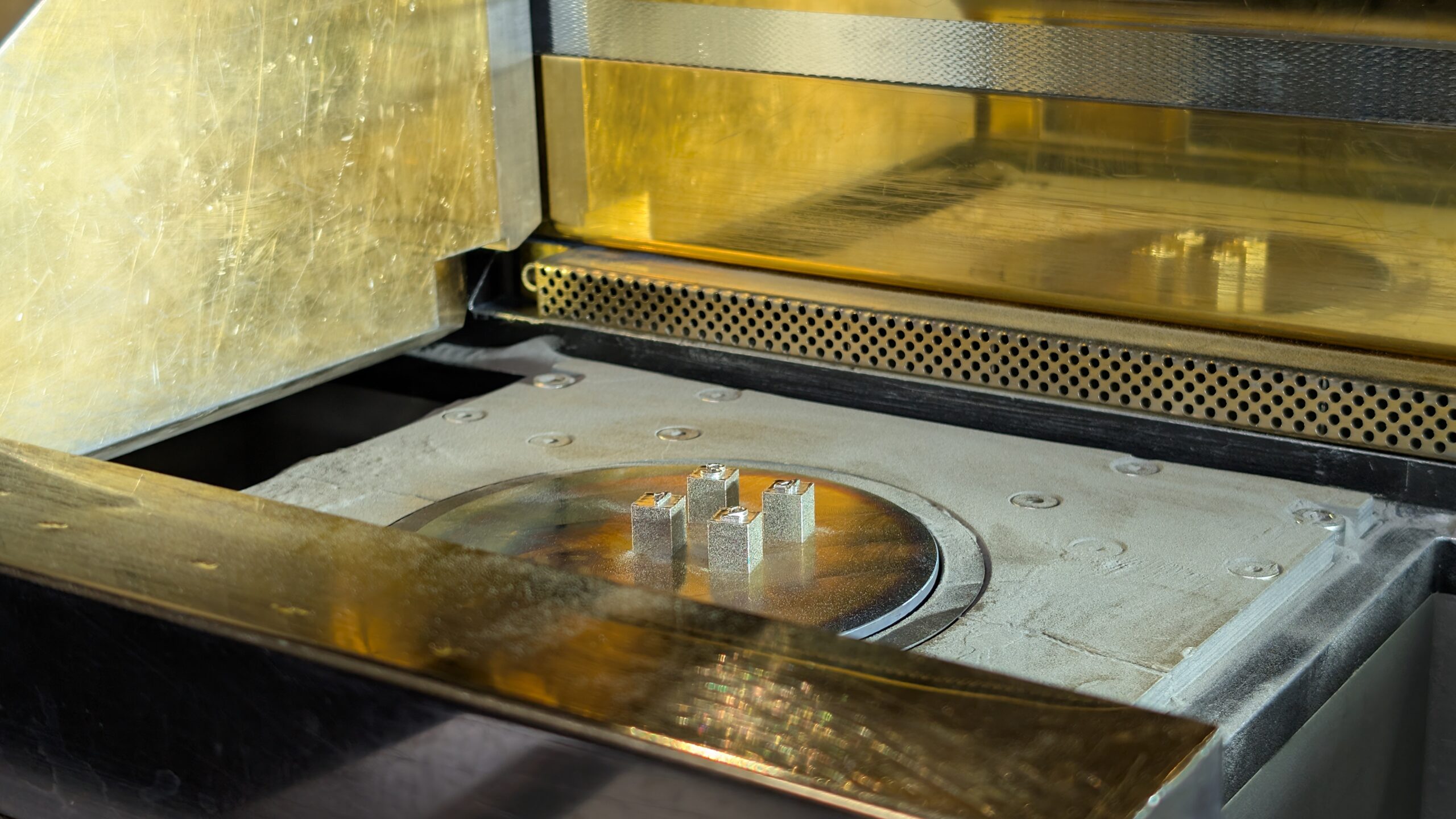

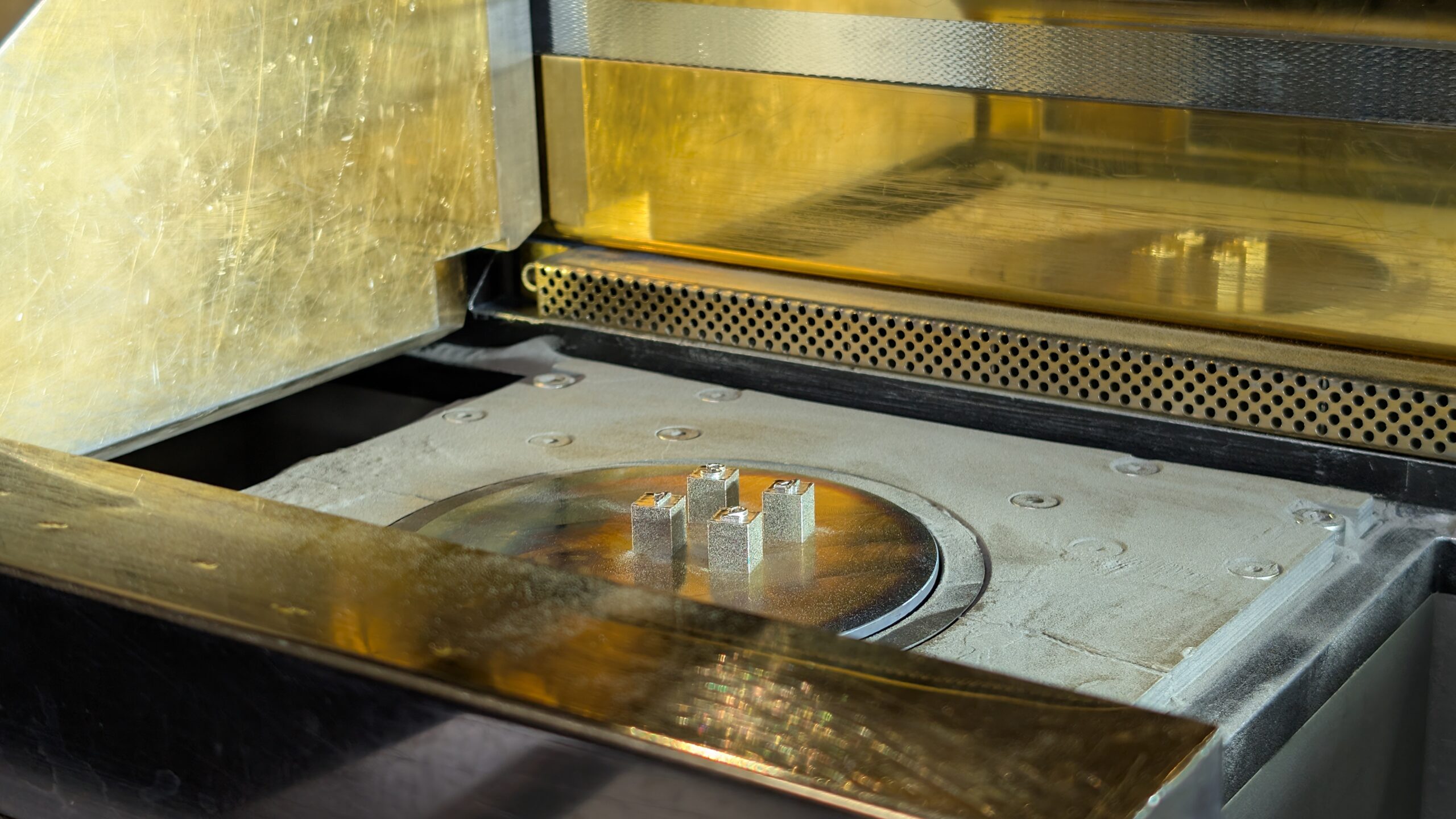

The group’s Dresden department has acquired a high-temperature LPBF system able to preheating powder beds to temperatures as much as 1,200°C. This know-how permits processing of refractory metals like tungsten and titanium aluminide, supplies beforehand restricted to electron beam melting processes. The system permits for increased decision printing of thin-walled constructions with exact microstructure management.

Fraunhofer’s supplies analysis focuses on aerospace purposes, together with aluminum matrix composites strengthened with silicon carbide particles for improved put on resistance. The crew can also be growing processing methods for Constellium Aheadd® HT2, a heat-resistant aluminum alloy designed to resist working temperatures of 250-300°C in aerospace purposes.

The exhibition sales space demonstrates large-scale 3D printing capabilities, with three shelving models and a counter produced utilizing solely 55 kg of recycled carbon fiber-reinforced polypropylene granulate. Manufacturing time totaled just below 13 hours, and the modular system might be commercially produced for about €1,500. The light-weight sandwich building gives excessive load-bearing capability whereas remaining space-efficient for transport.

Fraunhofer may also showcase the WEAM course of for integrating electrical capabilities instantly into 3D-printed parts.

Supply: iwu.fraunhofer.de