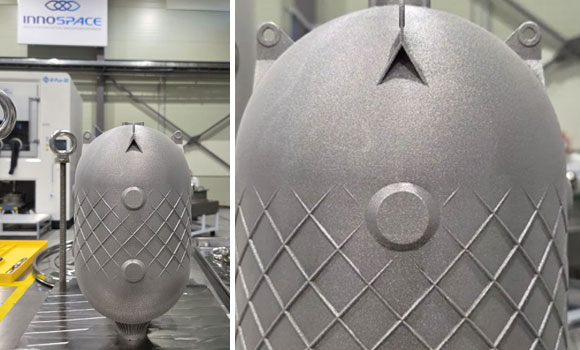

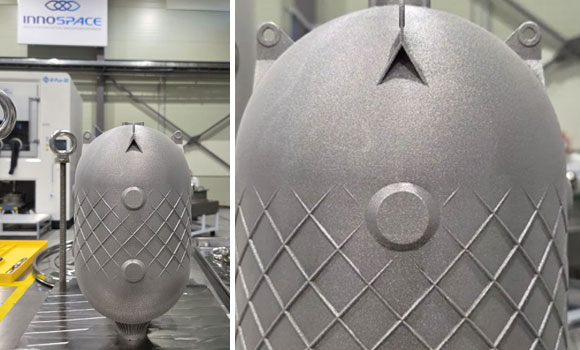

Innospace, a South Korean firm primarily based in Sejong, has efficiently demonstrated a way for 3D printing spherical vessels with out requiring assist constructions. The corporate used its proprietary low-overhang technique with Ti-6Al-4V Grade 23 titanium alloy to supply the vessels.

The know-how works on customary Laser Beam Powder Mattress Fusion (PBF-LB) additive manufacturing machines, eliminating the necessity for specialised {hardware} or distinctive machine architectures sometimes required for printing curved geometries. Innospace’s strategy produces spherical vessels with scalable capability starting from 1 to fifteen liters.

The corporate designed the vessels to be used as each oxidizer and gas tanks in aerospace functions. All the growth course of was carried out utilizing Oqton’s 3DXpert software program platform, which built-in CAD modeling, lattice and structural design, construct simulation, finite factor evaluation, and slicing features.

“That is what ‘AM as a Product’ means to us – know-how you possibly can belief, delivered at rocket pace with aerospace high quality,” acknowledged Jo Intaek, Division Director – Superior Manufacturing Enterprise Division, Innospace. The corporate positioned this growth as a part of its broader aerospace manufacturing capabilities.

Supply: metal-am.com