Shimizu Company has developed a spray-based 3D concrete printing system designed to assemble massive, curved bolstered elements. The system combines a nine-degree-of-freedom gantry robotic with a fabric spray simulator that may confirm sprayed-material habits earlier than precise printing. The fabric spray simulator was developed in collaboration with Carnegie Mellon College’s Computational Engineering and Robotics Lab.

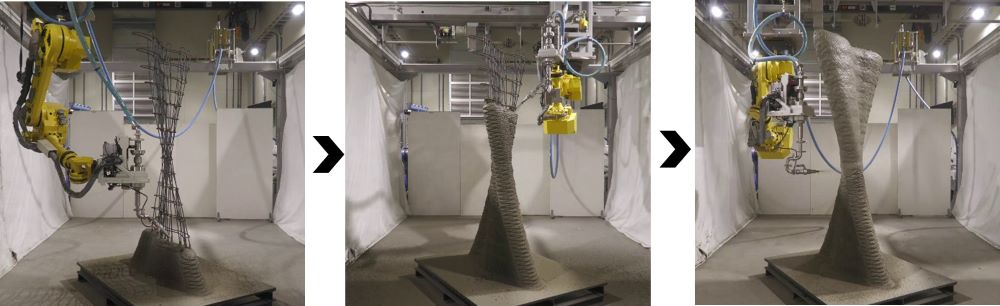

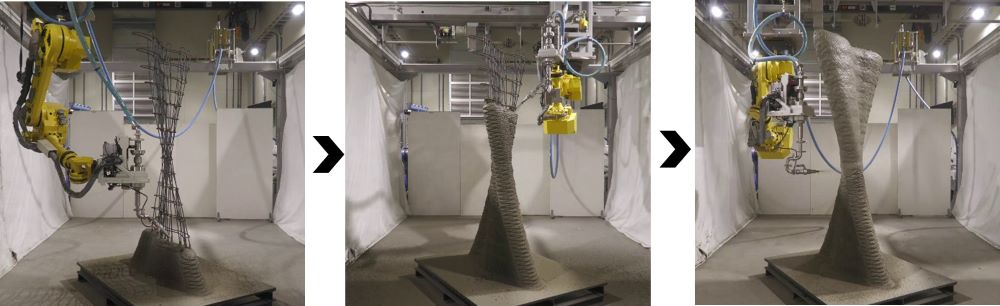

The system addresses limitations of typical materials extrusion 3D printing strategies, which deposit cementitious supplies layer by layer however wrestle to combine rebars into printed layers. Spray-based printing permits for higher integration of bolstered structural elements by spraying cementitious supplies to kind constructions. Nevertheless, this technique has traditionally confronted challenges with printer movement management and fabrication accuracy.

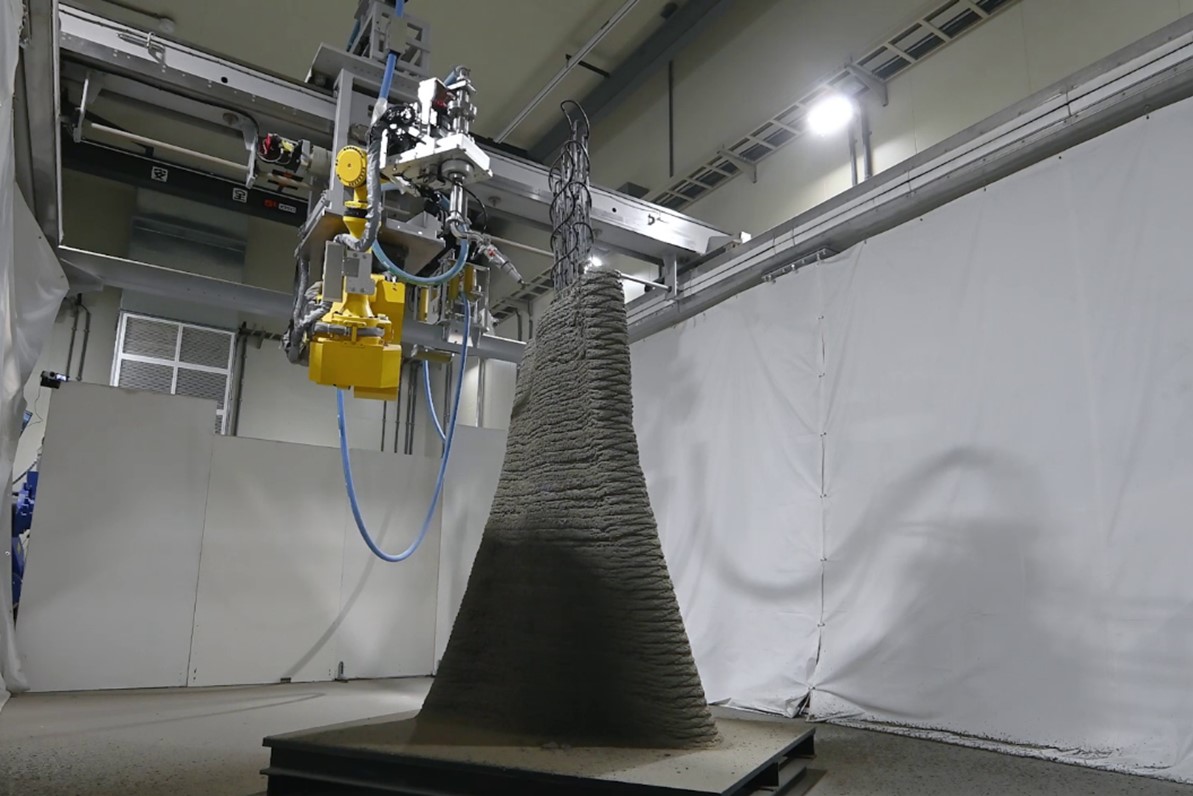

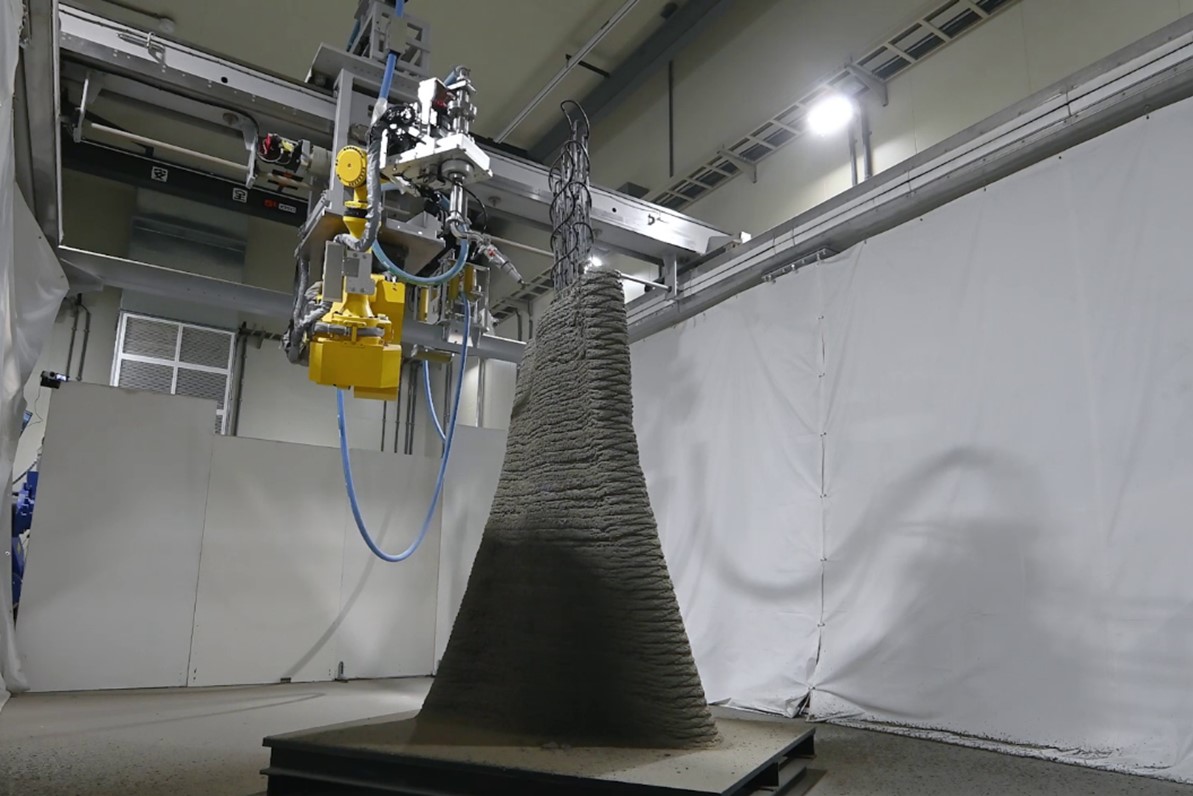

The brand new system makes use of a fabric spray simulator to find out optimum printing parameters, together with nozzle paths, spray distance, angle, velocity, and materials discharge quantity. The gantry robotic encompasses a seven-degree-of-freedom arm suspended from a two-axis XY movement mechanism on a portal-type body. The printable space measures 6 meters in depth, 4 meters in width, and three meters in top.

In demonstration checks, the system fabricated a twisted curved wall measuring 2.5 meters in top in 4 hours. The wall featured each decrease and higher layers projecting outward from the middle. Shimizu Company plans to proceed creating 3D printing applied sciences for building purposes, with a purpose of totally automating concrete building processes.

The event comes as Japan’s building trade faces workforce challenges because of an ageing inhabitants and declining birthrate. The corporate expects that implementing 3D printing of structural elements at building websites will cut back labor necessities and enhance design flexibility for constructions.

Supply: shimz.co.jp