November 18, 2025

UPDATE

Mapping the long run with 3D‑printed titanium Apple Watch circumstances

It began with a pie-in-the-sky concept: What if 3D printing — traditionally used to create prototypes — could possibly be leveraged to supply hundreds of thousands of equivalent enclosures to Apple’s actual design requirements, with high-quality recycled metallic?

“It wasn’t simply an concept — it was an concept that needed to develop into a actuality,” says Kate Bergeron, Apple’s vp of Product Design. “As soon as we requested the query, we instantly began testing it. We needed to show, with steady prototyping, course of optimization, and an incredible quantity of knowledge gathering, that this know-how was able to assembly the excessive normal of high quality we demand.”

This yr, all Apple Watch Extremely 3 and titanium Apple Watch Sequence 11 circumstances are 3D-printed with 100% recycled aerospace-grade titanium powder, an achievement not beforehand thought of doable at scale. Each staff at Apple rallied behind a shared ambition. The polished mirror end on Sequence 11 needed to be pristine. Extremely 3 needed to preserve its sturdiness and light-weight type to fulfill the calls for of on a regular basis adventurers. They each additionally needed to be higher for the planet with out compromising efficiency, and use the identical or better-quality supplies.

“At Apple, each staff holds surroundings as a core worth,” says Sarah Chandler, Apple’s vp of Atmosphere and Provide Chain Innovation. “We knew 3D-printing was a know-how with a lot potential for materials effectivity, which is important for attending to Apple 2030.”

Apple 2030 is the corporate’s bold aim to be carbon impartial throughout its complete footprint by the tip of this decade, which incorporates the manufacturing provide chain and lifelong use of its merchandise. Already, the entire electrical energy used to fabricate Apple Watch comes from renewable vitality sources like wind and photo voltaic.

Utilizing the additive means of 3D printing, layer after layer will get printed till an object is as near the ultimate form wanted as doable. Traditionally, machining cast components is subtractive, requiring giant parts of fabric to be shaved off. This shift permits Extremely 3 and titanium circumstances of Sequence 11 to make use of simply half the uncooked materials in comparison with their earlier generations.

“A 50 p.c drop is a large achievement — you’re getting two watches out of the identical quantity of fabric used for one,” Chandler explains. “Once you begin mapping that again, the financial savings to the planet are super.”

In complete, Apple estimates greater than 400 metric tons of uncooked titanium shall be saved this yr alone because of this new course of.

Over the previous decade, Apple has been experimenting with 3D printing whereas the trade itself was beginning to take off. In hospital labs, docs had been utilizing the primary 3D-printed prosthetics and synthetic organs, and even past Earth’s environment, astronauts found the pace and ease of 3D-printing important instruments whereas aboard the Worldwide House Station.

“We’ve watched this know-how mature for a very long time and seen its prototypes develop into extra consultant of our designs,” says Dr. J Manjunathaiah, Apple’s senior director of Manufacturing Design for Apple Watch and Imaginative and prescient. “Utilizing much less materials to make our merchandise has at all times been the intention. Beforehand, we hadn’t been capable of make beauty components at scale with 3D printing. So we began to experiment with 3D-printing metallic to make beauty components.”

For Apple, performance, magnificence, and sturdiness are desk stakes. Add on scalability, together with rigorous reliability testing, efficiency, and even breakthroughs in supplies science, all whereas guaranteeing Apple doesn’t lose any floor in its 2030 decarbonization targets.

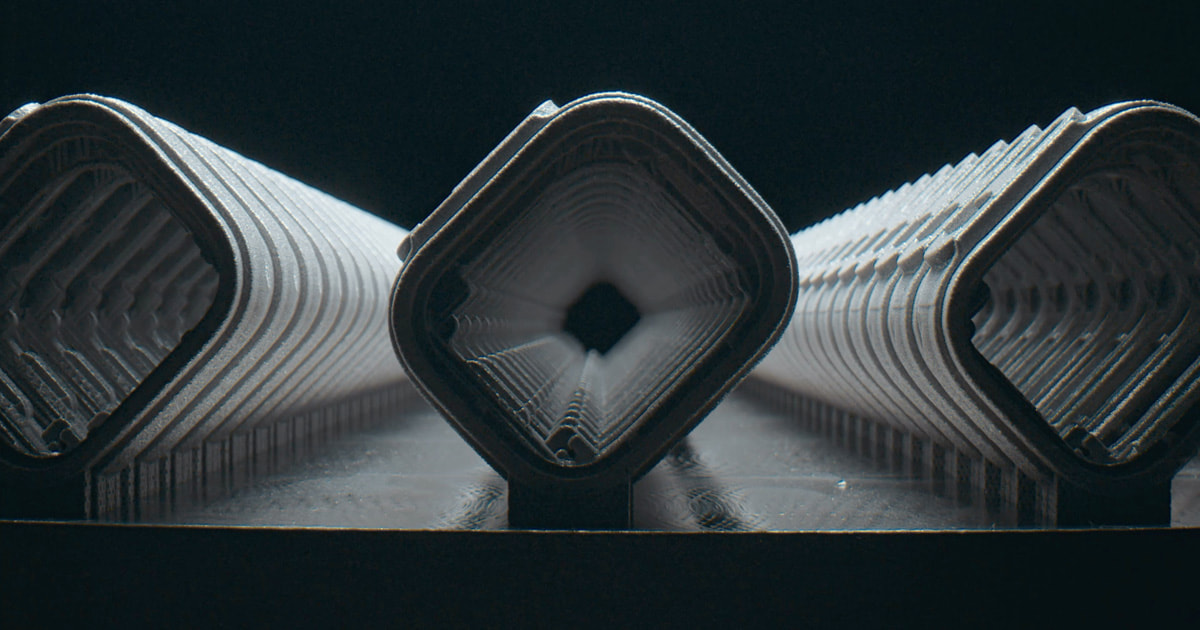

Trying down from above, rows of blocks protrude from the bottom like white Lego skyscrapers, whirring day and evening. These are the 3D printers exhausting at work constructing the titanium circumstances for Apple Watch Extremely 3 and Sequence 11.

Every machine encompasses a galvanometer that homes six lasers, all working concurrently to construct layer after layer — over 900 instances — to finish a single case. However even earlier than the printers can begin, the uncooked titanium must be atomized into powder, a course of that includes fine-tuning its oxygen content material to lower the qualities of titanium that develop into explosive when uncovered to warmth.

“This was cutting-edge supplies science,” says Bergeron.

“The powder needed to be 50 microns in diameter, which is like very nice sand,” Manjunathaiah explains. “Once you hit it with a laser, it behaves otherwise if it has oxygen versus not. So we had to determine tips on how to maintain the oxygen content material low.”

“Dialing in that thickness so that every layer is precisely 60 microns means very finely squeegeeing this powder,” Bergeron provides. “Now we have to go as quick as we probably can to make this scalable, whereas going as gradual as we probably can to be exact. This allowed us to be environment friendly, whereas nonetheless hitting the targets of the design.”

As soon as the printers are achieved working, an operator vacuums extra powder off the construct plate in a course of referred to as tough depowdering. As a result of the builds are printed to the near-final form for the entire interlocks wanted on the enclosure, powder can nonetheless sit within the nooks and crannies of the circumstances. An ultrasonic shaker ensures this remaining powder is eliminated through the nice depowdering section.

Throughout the singulation course of, a skinny electrified wire saws between every case, whereas a liquid coolant is sprayed concurrently to maintain the warmth from the reducing course of low. An automatic optical inspection system then measures every case, checking that its dimensions and cosmetics are correct. That is the ultimate high quality test to make sure the enclosures are prepared for last processing.

“The mechanical engineers need to be probably the most expert puzzle solvers in the whole world,” Bergeron says. “They take the circuitboard, the show, the battery — the entire issues that go contained in the case throughout last meeting — and make them match. We check alongside the best way to verify the watch is useful; then add software program and run it for a time period to test that every one the performance meets our necessities.”

One other key design enhancement 3D-printing unlocked: printing textures in areas that had been traditionally inaccessible within the forging course of. For Apple Watch, this meant having the ability to enhance the waterproofing course of for the antenna housing in mobile fashions. Inside the case, mobile fashions have a cut up stuffed with plastic to allow antenna performance, and 3D-printing a particular texture on the inside floor of the metallic enabled Apple to attain higher bonding between plastic and metallic.

Placing the puzzle items collectively was a multiyear journey that began with a collection of demos and proofs of idea to fine-tune the recipe, from the particular alloy composition, to the printing course of itself. After testing it out on a a lot smaller scale in earlier product generations, the staff was assured in its capacity to unravel for the distinctive challenges of working with titanium.

“We at all times attempt to take these incremental steps to permit us to take the following step,” says Bergeron. “This has now opened up the chance for much more design flexibility than what we had earlier than. Now that we’ve achieved this breakthrough at scale, in a very sustainable means, and on the beauty and structural stage that we’d like, the chances are infinite.”

That design flexibility unlocked one other profit that goes past Apple Watch: the USB-C port on the brand new iPhone Air. By creating a wholly new port with a titanium enclosure that’s 3D-printed with the identical recycled titanium powder, Apple was capable of make its extremely skinny but sturdy design a actuality.

That is the magic that may occur when the legal guidelines of physics, materials innovation, unparalleled design, and an unwavering dedication to the surroundings all line up.

“We’re terribly dedicated to programs change,” says Chandler. “We’re by no means doing one thing simply to do it as soon as — we’re doing it so it turns into the best way the entire system then works. Our North Star has at all times been to design merchandise which can be higher for folks and planet. After we come collectively to innovate with out compromise throughout design, manufacturing, and our environmental targets, the advantages are exponentially higher than we might ever think about.”

Press Contacts

Sean Redding

Apple

Nikki Rothberg

Apple

Apple Media Helpline