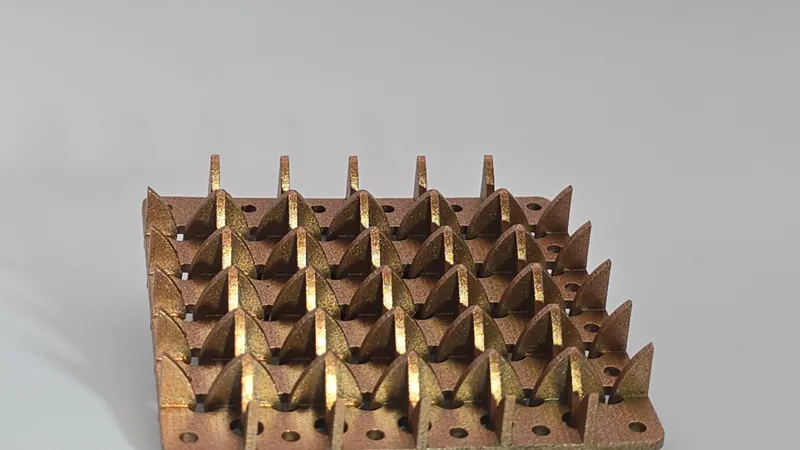

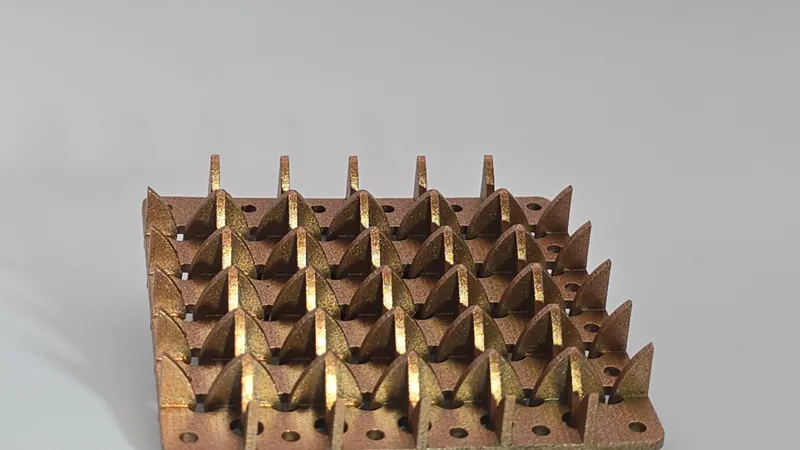

Horizon Microtechnologies has introduced that its coated plastic components have efficiently handed outgassing testing in keeping with the ECSS-Q-ST-70-02C customary for area supplies screening. This certification is required for supplies and elements meant to be used in area functions.

The outgassing take a look at evaluated coated plastic micro-AM components below thermal vacuum situations. Check specimens had been uncovered to 125°C in a vacuum vary of 10⁻⁶–10⁻⁷ mbar for twenty-four hours, with measurements taken earlier than and after the method in addition to 24 hours following completion.

The testing course of measures the quantity of risky content material launched and reabsorbed by the components. It additionally determines whether or not examined supplies may contaminate neighboring elements by measuring materials that condenses on a take a look at plate held at 25°C close to the samples.

The outcomes confirmed Complete Mass Loss (TML) of 0.354%, Recovered Mass Loss (RML) of 0.166%, and Collected Risky Condensable Materials (CVCM) of 0.000%. These measurements fall inside the acceptance limits outlined by the ECSS-Q-ST-70-02C customary for spacecraft supplies.

The profitable completion of this testing represents a step ahead for additive manufacturing in area functions. Assembly these stringent outgassing necessities opens potential alternatives for 3D-printed elements in spacecraft and satellite tv for pc programs.

Supply: eurekamagazine.co.uk